Robotic Maintenance & Large-Scale Anode Hanger/Yoke Revamp at Alcoa Mosjøen

Table of content

Key Points

-

Customer

Alcoa Mosjøen, Norway

-

Scope

In-line robotic repair & large-scale yoke conversion

-

Scale

8,600 yokes converted in 20 weeks

-

Technology

Robotic welding, automated handling, vision systems, condition monitoring

-

Impact

Increased throughput, improved safety, sustained uptime, 24/7 execution

The Challenge Alcoa’s aluminium smelter in Mosjøen, Norway, is investing more than NOK 1 billion to increase annual smelting capacity from 200,000 to 210,000 tonnes by 2025. To reach this target, the smelter needed critical upgrades to its anode assembly operations. The challenge was twofold: introduce automation-driven improvements to support higher throughput while maintaining full […]

Key Points

-

Customer

Alcoa Mosjøen, Norway

-

Scope

In-line robotic repair & large-scale yoke conversion

-

Scale

8,600 yokes converted in 20 weeks

-

Technology

Robotic welding, automated handling, vision systems, condition monitoring

-

Impact

Increased throughput, improved safety, sustained uptime, 24/7 execution

The Challenge

Alcoa’s aluminium smelter in Mosjøen, Norway, is investing more than NOK 1 billion to increase annual smelting capacity from 200,000 to 210,000 tonnes by 2025. To reach this target, the smelter needed critical upgrades to its anode assembly operations. The challenge was twofold: introduce automation-driven improvements to support higher throughput while maintaining full production uptime.

The Assignment

Storvik was selected to execute a full-scale revamp of 8,600 anode yokes, converting them from a 2-stub to a 3-stub configuration without interrupting ongoing operations. The project demanded continuous 24/7 rebuilding of 5,000 tonnes of metal. This included cutting assemblies from the stem, straightening, and welding on new 3-stub assemblies.

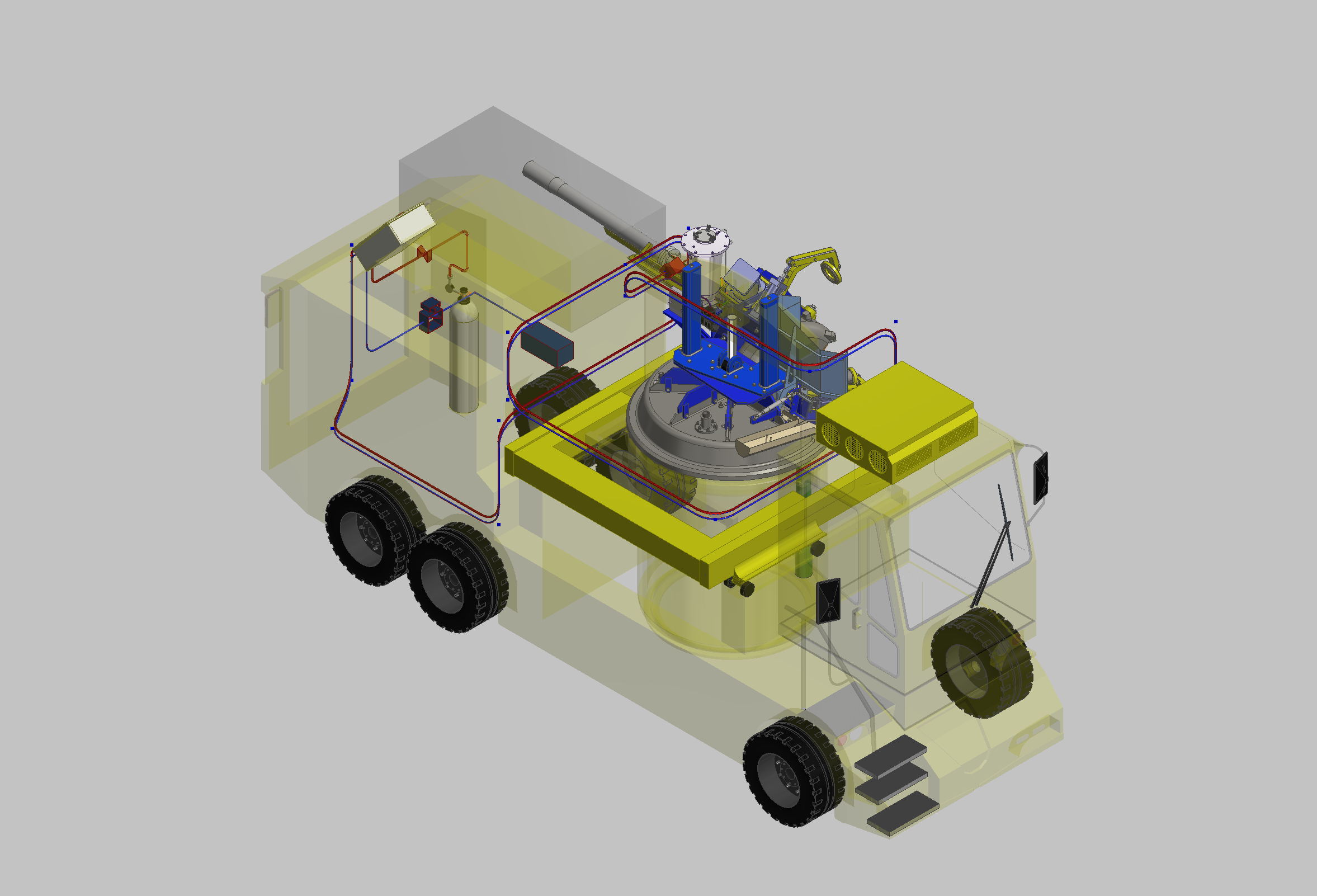

In addition, Storvik was responsible for supplying, integrating, and operating a fully automated revamp line connected directly to Alcoa’s running anode handler line. This enabled “hot” inline operations to be carried out alongside full-scale production. The scope covered the complete project cycle: engineering, implementation, commissioning, and deployment.

Highlights

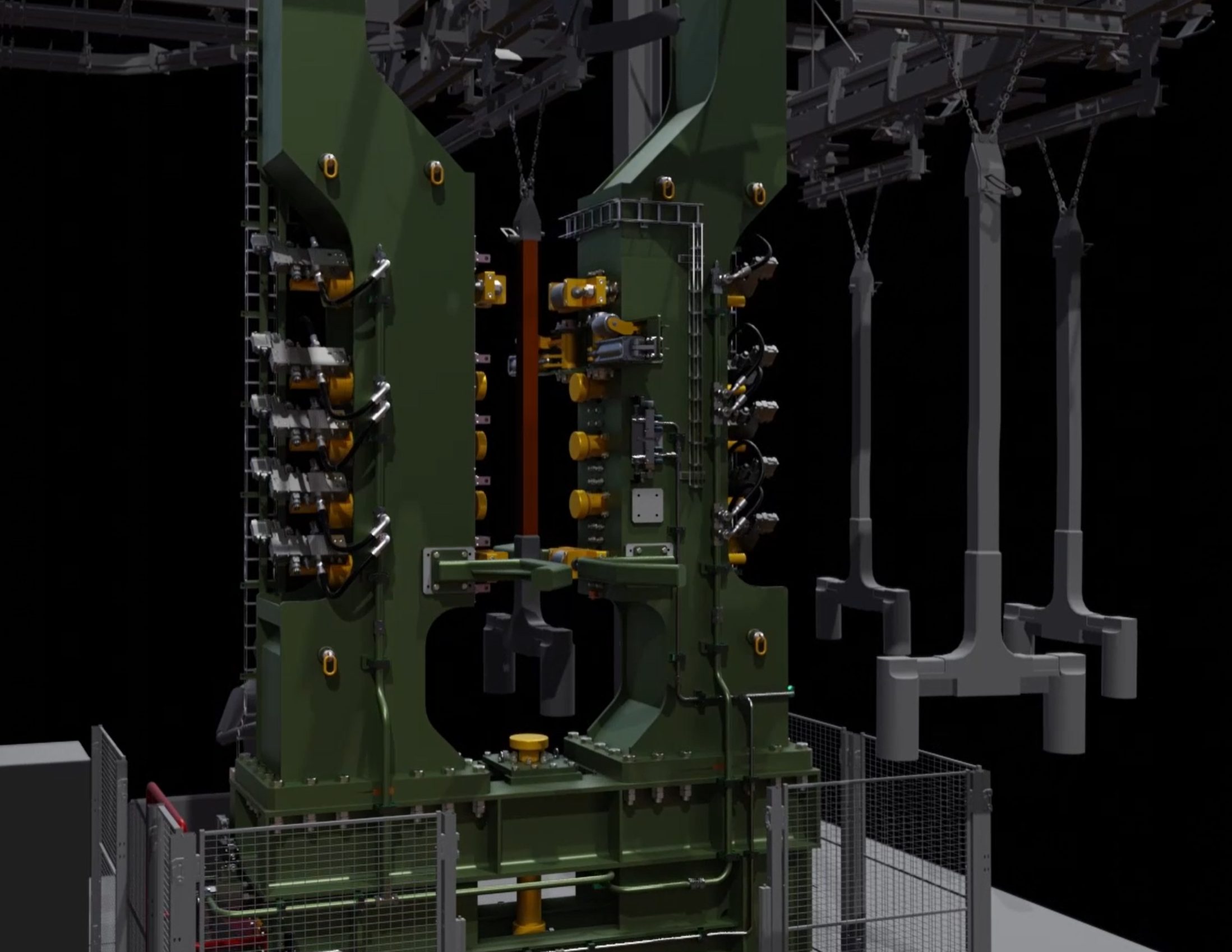

Industry-First ILRR System

- Commissioned in 2016 at Alcoa Mosjøen.

- Integrated hanging conveyor line, cutting machine, robotic welding machines, robotic handling arms, advanced vision systems, and real-time condition monitoring.

- Designed for zero offline downtime, improving repair precision, weld quality, and operator safety.

- Proven continuous operation since launch, setting a new benchmark in the global aluminium industry.

Our Approach

To revamp 8,600 anode yokes without disrupting production, Storvik developed a dedicated robotic revamp line with automated handling, alignment, and welding designed for high-volume conversion. By applying a lean execution model, the team achieved an average throughput of 400 modified yokes per week.

The project was carried out under strict safety and uptime requirements, ensuring uninterrupted operation throughout the 20-week execution. Close collaboration with Alcoa’s teams ensured seamless integration into the smelter’s processes, balancing speed with reliability and precision.

The Outcome

The project was completed ahead of industry benchmarks for scale and complexity, with zero unplanned downtime during execution. A total of 5,000 tonnes of metal was handled without disrupting smelter output.

The upgraded line increased throughput capacity while enhancing reliability and operator safety. Most importantly, Alcoa’s planned capacity expansion was fully supported without operational disruption.

This project further strengthened Storvik’s position as a global pioneer in robotic maintenance and live-line revamp execution for the aluminium sector.