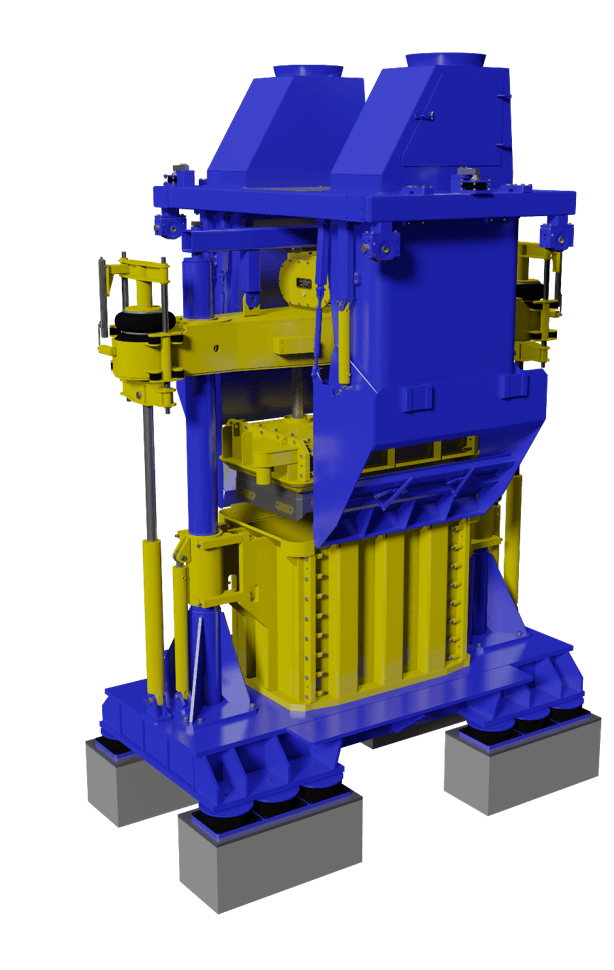

Hal Vibrocompactor

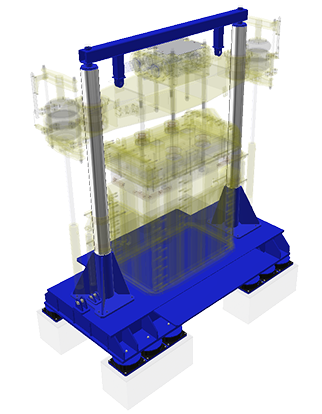

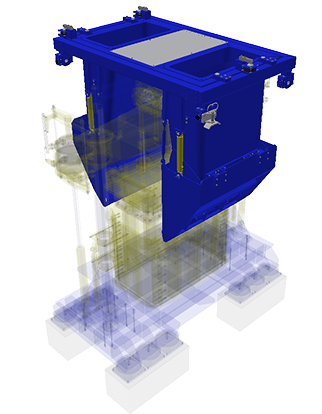

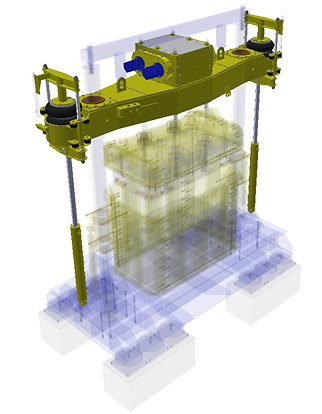

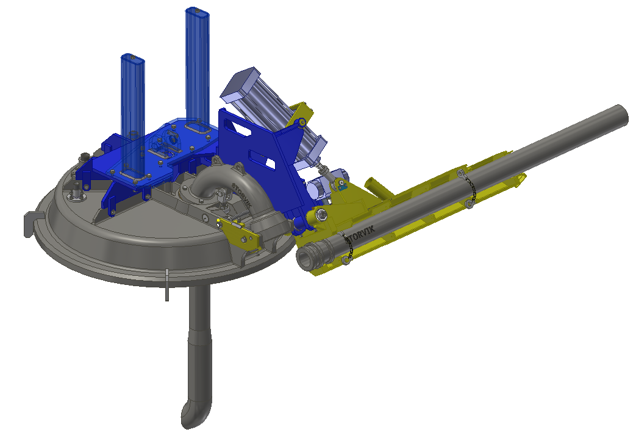

State of the art anode production technology. The vibrocompactor is the main component in the forming stage of the green anode in the paste plant. The paste for an anode is compressed in the vibrocompactor by dynamic and static mechanical forces.

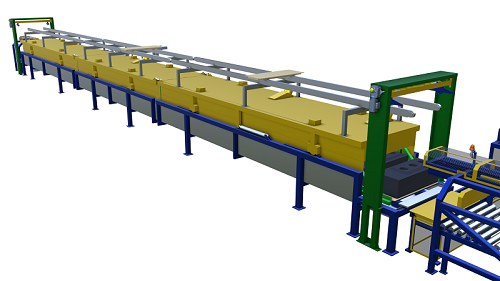

The HAL vibrocompactor has been developed since 1959 and today the input of dynamic force is integrated to the cover weight (the vibrating mass on top of the anode paste). This results in more effective vibration and short vibration time. The feeding of paste is done from 2 hoppers in stationary position with minimal filling time of the mould. Production capacity is 36 anodes/hour at 22 s vibration time.

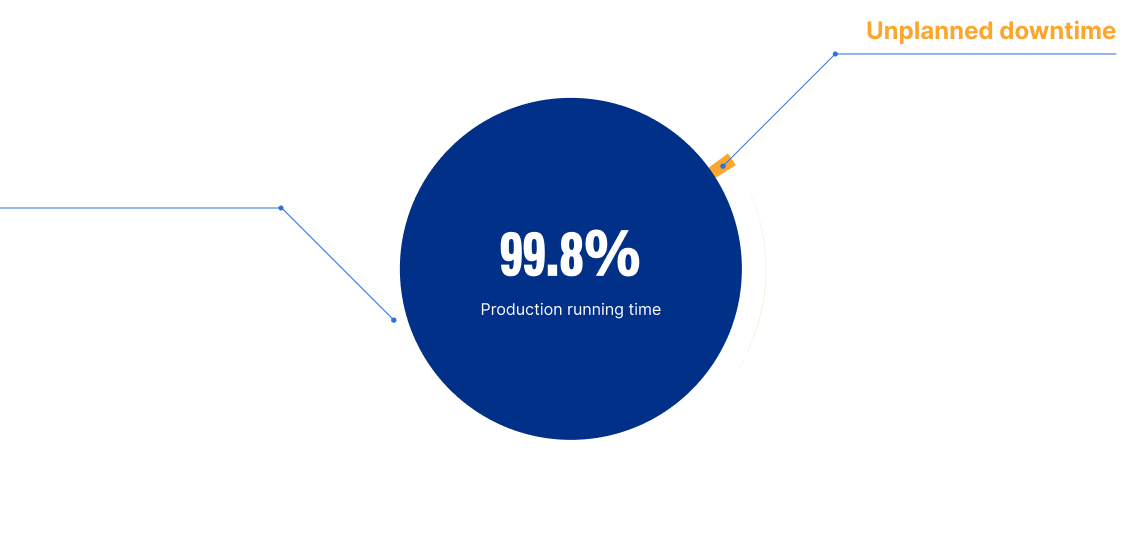

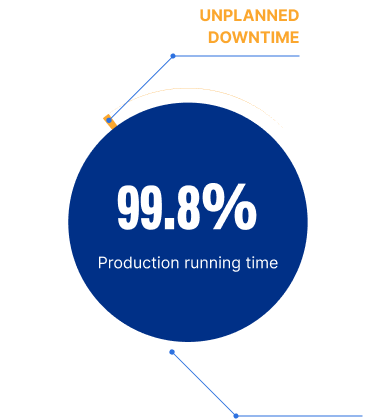

The compactor has few movable parts and the maintenance and operation cost is very low. Availability factor is measured to 99,5% over 5 years.