Revolutionizing Durability: Storvik’s Sow and Ingot Molds in the Aluminum Industry

Table of content

Key Points

-

Unmatched Durability

Storvik's proprietary low-carbon steel ensures high resistance to thermal stress and shock.

-

Tailored Solutions

Advanced simulations and client-focused design led to optimal mold performance.

-

Proven Reliability

Storvik's products have a track record of success, backed by references from industry leaders.

The Challenge The aluminum industry demands molds capable of withstanding extreme thermal stresses and shocks during the casting process. Traditional solutions often fall short, leading to frequent replacements, increased operational costs, and inconsistent product quality. Storvik was tasked with addressing these issues while maintaining environmental and cost-efficiency. Our Approach Storvik employed a holistic strategy to […]

Key Points

-

Unmatched Durability

Storvik's proprietary low-carbon steel ensures high resistance to thermal stress and shock.

-

Tailored Solutions

Advanced simulations and client-focused design led to optimal mold performance.

-

Proven Reliability

Storvik's products have a track record of success, backed by references from industry leaders.

The Challenge

The aluminum industry demands molds capable of withstanding extreme thermal stresses and shocks during the casting process. Traditional solutions often fall short, leading to frequent replacements, increased operational costs, and inconsistent product quality. Storvik was tasked with addressing these issues while maintaining environmental and cost-efficiency.

Our Approach

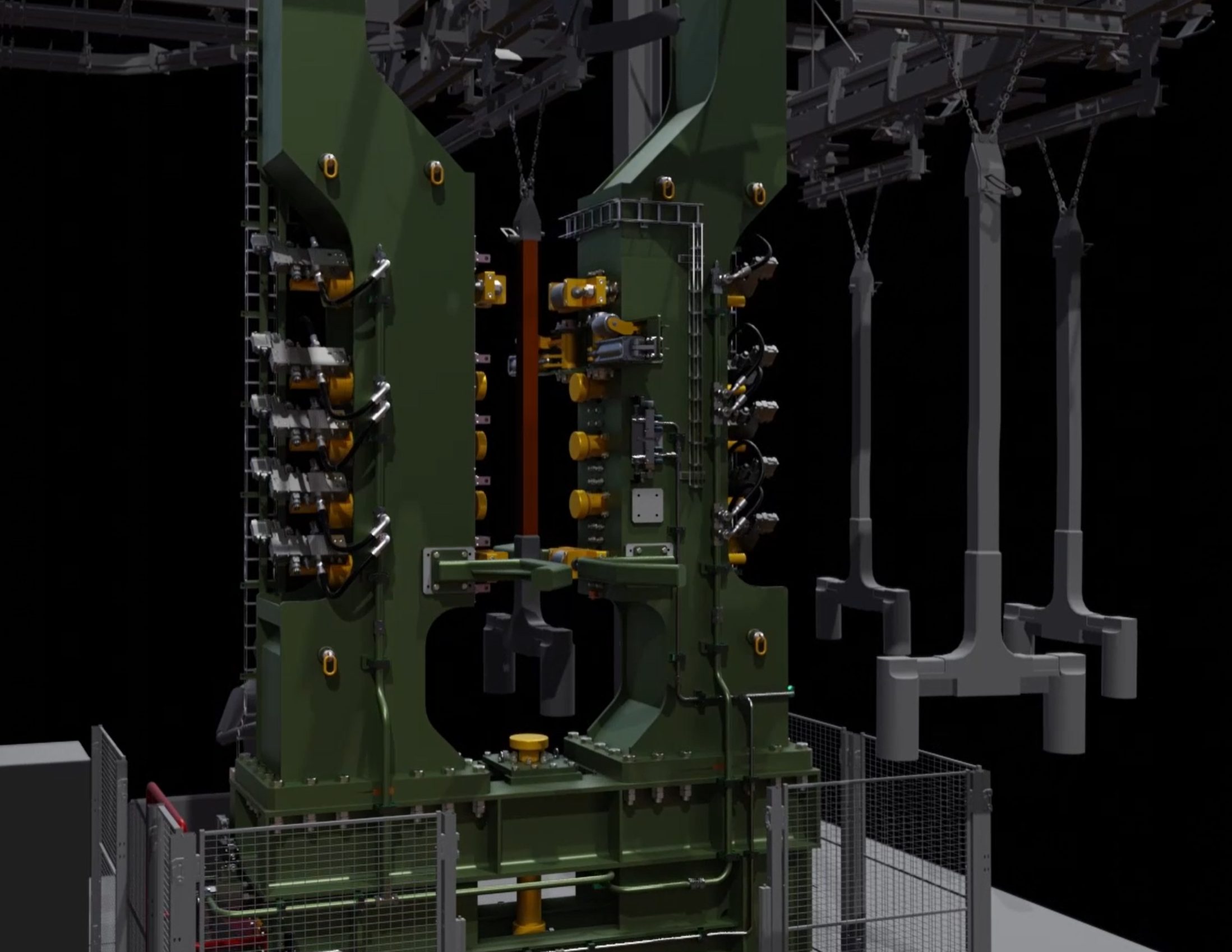

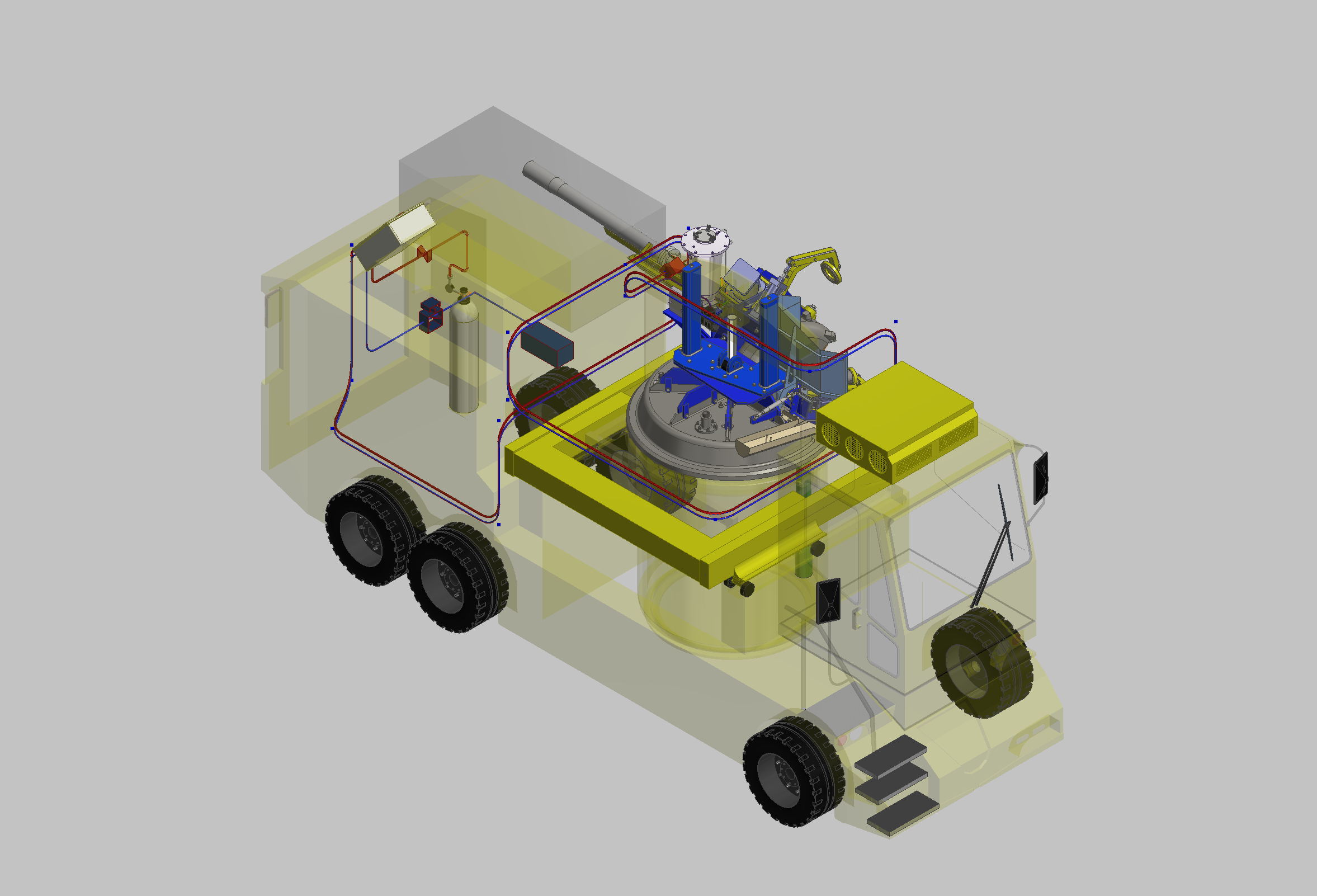

Storvik employed a holistic strategy to redefine the design and material quality of sow and ingot molds. The key steps included:

- Innovative Material SelectionThe molds are crafted using Storvik’s proprietary cast steel quality (PIN-DP). This material features a low carbon content, significantly enhancing resistance to thermal stress and shock, ensuring superior durability.

- Thermal Stress SimulationUtilizing advanced simulation techniques, Storvik assessed the thermal stress the molds endure during casting. This allowed for tailored recommendations on design adjustments and material improvements, ensuring optimal performance under challenging conditions.

- Client Collaboration and ReferencesStorvik engaged closely with clients to refine mold designs. Upon request, references were provided to demonstrate proven reliability and success in similar applications.

Out Outcome

Storvik’s sow and ingot molds are now recognized as a benchmark in the aluminum industry for durability and efficiency. Key outcomes include:

- Extended LifespanThe enhanced material and design reduce wear and tear, prolonging mold life and minimizing downtime.

- Cost EfficiencyReduced frequency of mold replacements lowers operational costs for aluminum producers.

- Improved Casting QualityThe molds ensure consistent product quality by effectively handling thermal stress, enabling more reliable production processes.