Revolutionizing Aluminum Casting

Table of content

Key Points

-

Increased Uptime

Through predictive maintenance and component upgrades, we achieved a 25% increase in equipment uptime.

-

Reduced Maintenance Costs

Our optimized maintenance program resulted in a 15% reduction in annual maintenance costs.

-

Improved Safety

By implementing safety enhancements, we achieved a 20% decrease in safety incidents.

Storvik was tasked with revitalizing an aging aluminum production facility. Our engineers were challenged with increasing the equipment’s lifespan, reducing downtime, and improving overall operational efficiency.

Key Points

-

Increased Uptime

Through predictive maintenance and component upgrades, we achieved a 25% increase in equipment uptime.

-

Reduced Maintenance Costs

Our optimized maintenance program resulted in a 15% reduction in annual maintenance costs.

-

Improved Safety

By implementing safety enhancements, we achieved a 20% decrease in safety incidents.

The Challenge

The client’s aluminum production facility was grappling with a number of pressing issues. Aging equipment was leading to frequent breakdowns, resulting in significant production downtime and increased maintenance costs. Additionally, the outdated safety systems posed a risk to the workforce.

Specific challenges included:

- Rapid equipment wear: Critical components were deteriorating at an accelerated rate, leading to unplanned shutdowns.

- Inefficient maintenance practices: Reactive maintenance strategies resulted in high maintenance costs and reduced equipment lifespan.

- Safety concerns: Outdated safety systems and inadequate safety protocols posed a significant risk to the workforce.

Our Approach

ARABAL 2023 was not just a milestone for Storvik; it marked the beginning of a more focused approach towards the Middle Eastern market. With the insights gained and the support received, we are enthusiastic about the opportunities that lie ahead.

Storvik is poised to play a significant role in shaping the future of the international aluminum industry in the region.

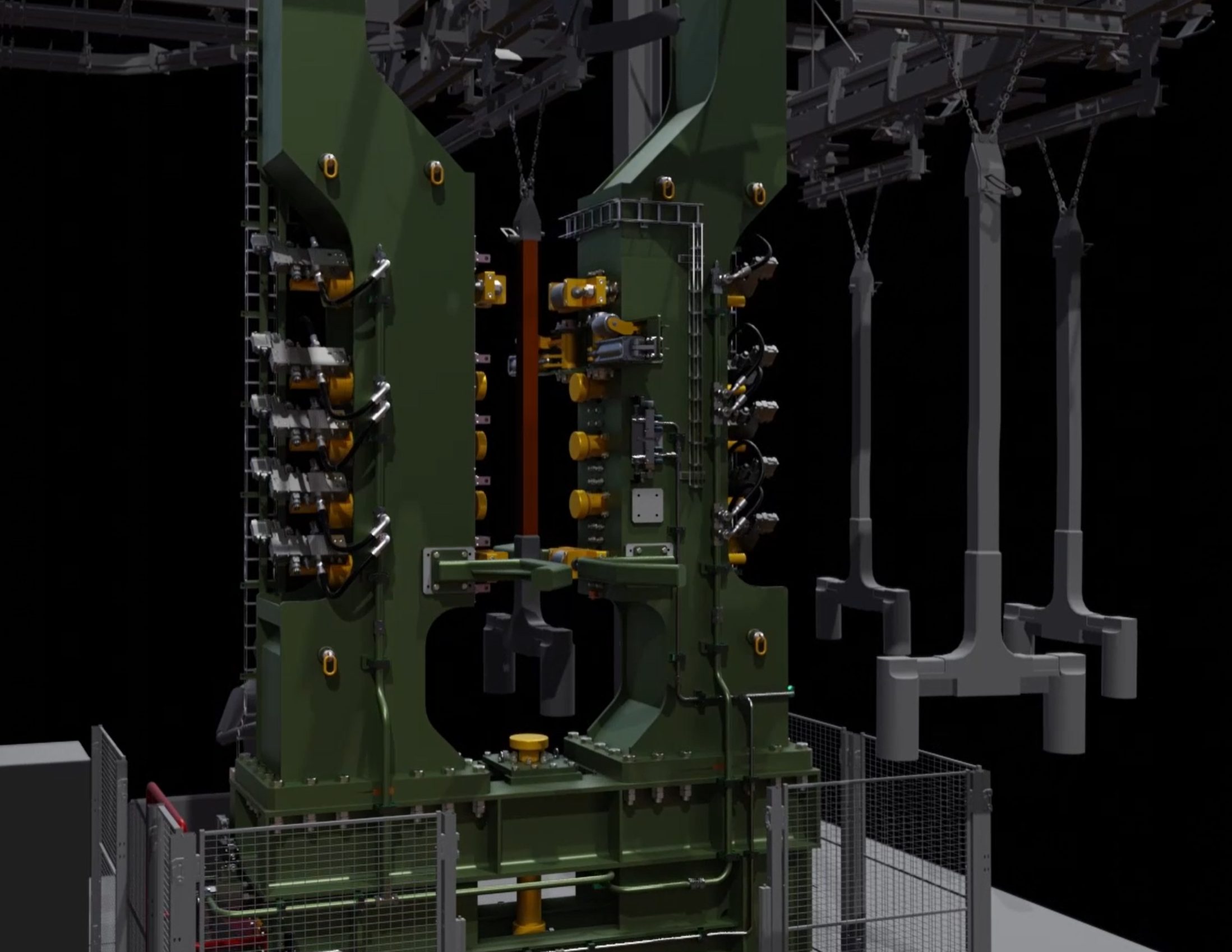

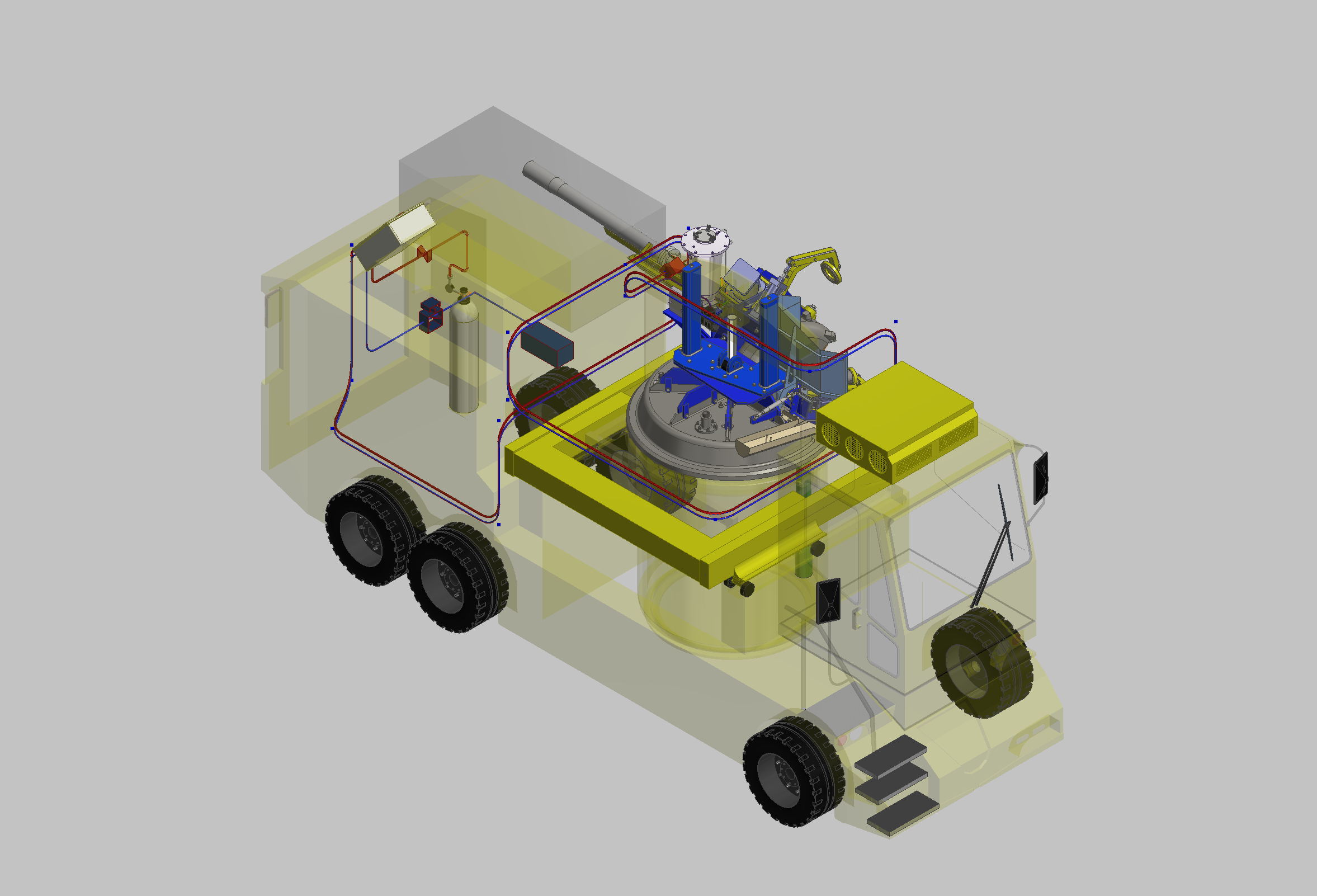

Storvik implemented a comprehensive maintenance and modification program. Our engineers conducted a thorough assessment of the facility and identified key areas for improvement.

Key actions included:

- Upgrading critical components

- Implementing a predictive maintenance program

- Optimizing equipment layout

- Customizing automation solutions

Storvik’s expertise in the aluminum industry was instrumental in transforming our facility. Their innovative solutions and commitment to quality have significantly improved our operations Dan Allan, CEO at Aker Solutions

The Outcome

By implementing these strategic changes, Storvik successfully addressed the client’s challenges. The modernized facility now operates more efficiently, with reduced downtime and increased productivity.