Storvik sponsors new Vinnu Arena at Leikvin Kulturminnepark

Storvik supports the local community in Sunndal and is a proud sponsor of the new Vinnu Arena.

The new outdoor cultural arena was officially opened on Family Day, with the cutting of the ribbon and the announcement of the name Vinnu Arena.

Vinnu Arena provides the opportunity for great theater and concert experiences for young and old, in a historic setting at Leikvin Kulturminnepark.

Here it abounds in strikingly beautiful nature and exciting cultural history. In one place you will find the Bygdemuseet which offers several exhibitions, the cemetery on Løykja where you can see the graves of the main characters in the story of Lady Arbuthnott, Phillipshagen in British landscape style filled with rhododendrons, and Løykja Cemetery with history through 1000 years from Iron Age history from Roman times to the end of the Viking Age.

Other articles

-

New Framework Agreement with Elkem – A Long-standing Partnership Continues

Company

Storvik and Elkem are continuing their strong collaboration. The new framework agreement, signed on April 30th, 2025, runs for three years with an option to extend for an additional two years.

-

Storvik and Hycast Enter Framework Agreement

Company

Storvik and Hycast have entered into a new framework agreement that formalizes and further develops the strong collaboration the companies have enjoyed over time.

-

New colleague at Cast Products

Company

We are pleased to welcome Lars Erik Valsø to Storvik! He joined us on February 3rd as Order Coordinator and Logistics at our Cast Products department.

-

Storvik Approved as an Apprenticeship Company in Industrial Assembly

Company

We are proud to announce that Storvik has now been approved as an apprenticeship company in the industrial assembly trade! This means we can offer even more apprenticeship opportunities and contribute to developing skilled professionals in the industry.

-

Vidar Ulvestad Joins Storvik as COO Project & Engineering!

Company

We are delighted to welcome Vidar Ulvestad to the Storvik team! On January 1, 2025, Vidar assumed the position of Head of Project & Engineering, with the title COO Project & Engineering (Chief Operating Officer).

-

2024: A year of growth, innovation and collaboration

Company

For Storvik, 2024 has been a year of exciting development, new opportunities, and strengthened partnerships with our customers. As a global supplier to the process industry, we are proud to deliver solutions that create value and drive sustainable development for our partners – both nationally and internationally.

-

Storvik honours its loyal employees

Company

During this year’s Christmas lunch, group CEO for Storvik, Stein Kjartan Vik, handed out anniversary gifts to employees who have been with Storvik for 30 and 40 years respectively. We wish – on behalf of all of Storvik – to pay tribute, recognize and thank outstanding and loyal employees.

-

Storvik Contributes to Groundbreaking EGA EX Technology Pilot

Company

On December 5th, Storvik proudly participated in a groundbreaking ceremony at Emirates Global Aluminium (EGA), marking a major milestone in aluminium industry innovation. The event celebrated the construction of 10 pilot reduction cells for EGA’s next-generation EX smelting technology at Al Taweelah in the UAE. This pilot aims to showcase the most advanced Industry 4.0 capabilities in the aluminium sector, further solidifying EGA’s leadership in technological innovation.

-

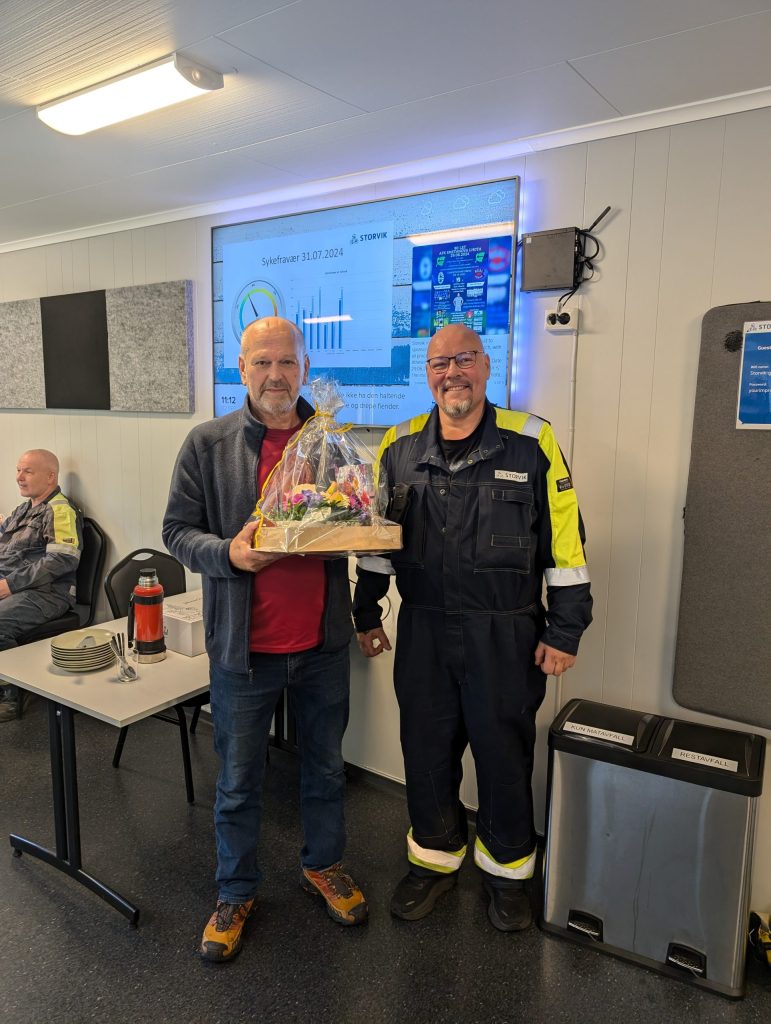

Ola Sande Retires After 45 Years at Storvik

Company

On August 31, 2024, Ola Sande entered retirement after being a central part of Storvik for more than 45 years. Ola began his career with us on May 1, 1979, at the age of 19. It didn’t take long before he climbed the ranks, becoming foreman and leader of what we at Storvik call “Smia” – our machining workshop. Under Ola’s leadership, Smia evolved in step with both technological advancements and the needs of our customers.

-

Summer Intern Johan Ansnes Contributes to Sustainability and Innovation at Storvik

Company

This summer, Johan Ansnes has held the position of summer intern at Storvik. He is studying Industrial Economics (IndØk) at Ås, specializing in Innovation, Sustainability, and Operations Technology. Throughout the summer, Johan has worked on our sustainability report while also being involved in research, analysis, and the development of commercial business models in several of our R&D projects, which are now nearing commercialization

-

Storvik Updates Email and Website to Strengthen Global Presence

Company

We at Storvik are pleased to announce that we have transitioned our email addresses from storvik.no to storvikgroup.com. This means that while you can still send emails to our old addresses at storvik.no, we will be responding from our new addresses at storvikgroup.com.

-

Jan Fajstaver Sr. Celebrates 80 Years – A Significant Milestone for Storvik and Fajst sro

Company

On Saturday, Jan Fajstaver Sr. turned 80, a significant event for Storvik and our long-standing partner, Fajst sro.

-

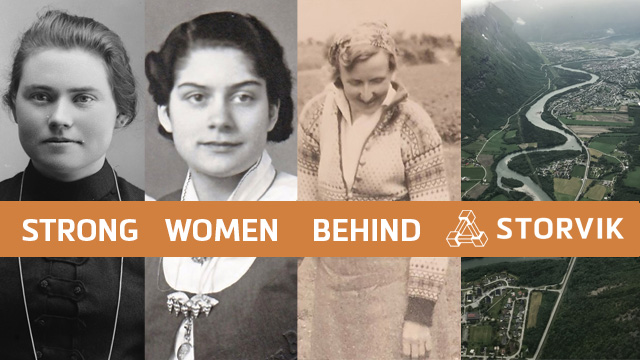

Across Time: The lasting mark of women on Storvik

Company

For over a century, Storvik has played a pivotal role in the development of Sunndal as an industrial powerhouse, symbolizing the modernization of Norwegian society throughout the 20th century. From Nils Storvik’s foundational smithy to today’s extensive operations, the company’s history has been marked by innovation, expansion, and a remarkable, yet often overlooked, contribution from women.

-

Storvik over 110 years: From Farm Forge to Global Industrial Pioneer

Company

The story of Storvik is about entrepreneurship, creativity, and sustainability over more than 110 years. Storvik has been a significant part of the development of Sunndal as an industrial location, and it has been argued that the development in Sunndal in many ways illustrates the modernization of Norwegian society through the 20th century. Over the years, Storvik has expanded in various areas, from local acquisitions to international sales agreements and commitments that have helped strengthen the company.

-

Storvik’s Success at ARABAL 2023: A Gateway to Innovation in the region

Industry

In the fast-paced world of the international aluminum industry, staying ahead of the curve is not just a goal but a necessity.

-

Innovation Norway: An indispensable partner for Storvik’s export initiatives

Company

In an increasingly globalized economy, access to international markets is crucial for the growth and sustainable success of businesses worldwide. For Storvik, a leading supplier to the process industry, the support from Innovation Norway has proven to be a crucial factor in our export strategy.

-

110 Years of Storvik

Company

In the heart of our community, Storvik has stood strong for 110 glorious years. From the day Nils Storvik opened our doors to the present, our journey has been marked by resilience, growth, and unwavering community support. As we celebrate this remarkable milestone, we are overwhelmed with gratitude for each person who has been a part of our story. Your presence and support have made this anniversary celebration unforgettable, and we want to take a moment to express our deepest thanks

-

Storvik invites you to an information meeting about its plans in Mosjøen

Company

Storvik invites you to an information meeting about its plans in Mosjøen

Location: Hotel Milano, Mosjøen

Date: Wednesday 13 September

Time: 18:00-19:00 -

How important are ISO certifications?

Company

Globally, it is estimated that 6,300 die every day due to work-related injuries or illnesses. In Norway, 39 people died in work accidents in 2021, according to Statistics Norway. Furthermore, the importance of managing the worker’s psychosocial well-being has climbed higher on the companies’ agenda during the pandemic. In Storvik, we have our own sustainability pledges that deal with safety, the environment and psychosocial well-being at work. Guaranteeing employees’ safety and reducing workplace hazards is increasingly central to ensuring a healthy company. ISO 45001 is an international standard, designed in line with international working environment standards and guidelines. Implementation and compliance with the standard thus ensures that we meet current laws, rules and regulations relating to the working environment and safety.

-

Significant contract with a key client

Company

Alcoa Mosjøen, a subsidiary of the American aluminum company Alcoa, has announced that Storvik Group has been awarded several major and central contracts. The contracts are related to previously announced investments aimed at increasing production capacity at the Mosjøen smelter. Storvik considers the contract value to be significant.

-

Roge AS and Storvik sign a collaboration agreement

Partners

Industrial cuffs are mainly cast in one piece, it often requires extensive dismantling of pipe systems/parts and in some cases also shutdown of production to replace them. With the ROGE cuff®, this operation is carried out in a few minutes, through their unique patented solution, without either disassembling or stopping production. The cuff is both dust and waterproof and is supplied in a range of materials for different uses, and new areas of use for the product are constantly being discovered. Roge has already tested his products at Dosan, Skretting, Pipelife, etc

-

The sustainability conference and Action Now

Company

For the past 2 years, Storvik has worked in the network project Action Now, which is all about sustainability. On 14 February, the collaboration was crowned with a sustainability conference for businesses and the public sector in our region. KNN, SpareBank1 Nordmøre and KBK joined forces for the event, and worked out a solid program with a focus on sustainability. The topics ranged from what is happening in sustainability strategies in the big picture, right down to the concrete examples of how to prioritize and carry out profitable sustainability work in your own organisation. The Action Now work was made visible in one of the presentations at the conference, by Hilde Løseth Modell in BDO.

-

A sustainable future with female leaders

Company

Storvik is a global and forward-looking company, with quality as its hallmark. Storvik has a strategic commitment to a sustainable future and the UN’s sustainability goal number 5 is about achieving equality and strengthening the position of girls and women.

-

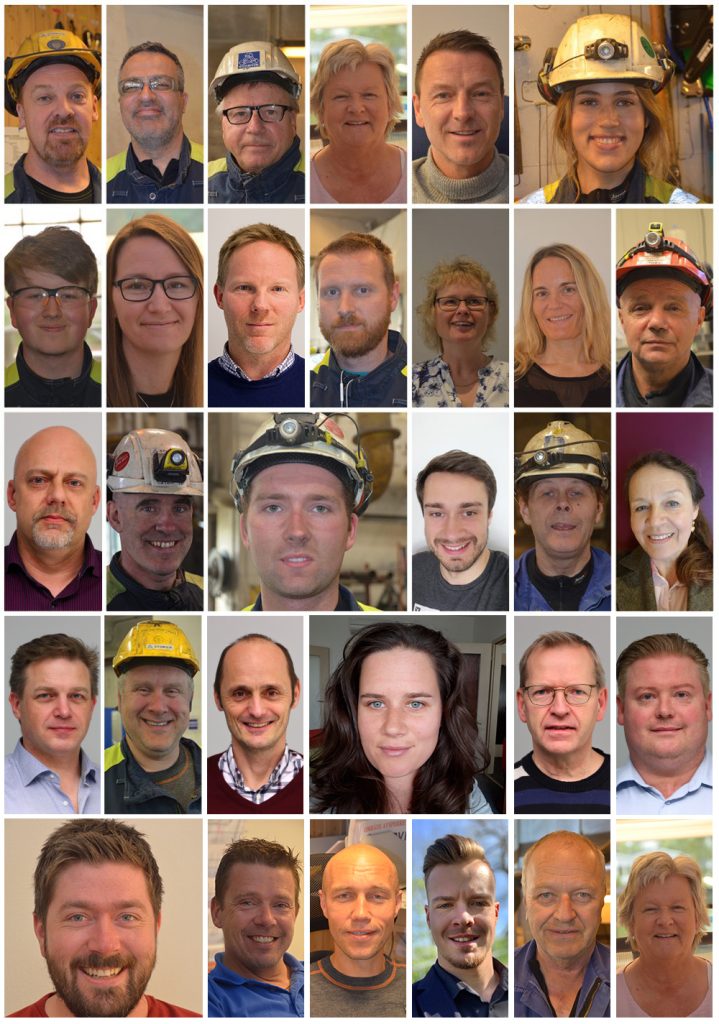

Storvik honours its employees

Company

During this year’s Christmas lunch, group CEO for Storvik, Stein Kjartan Vik, handed out anniversary gifts to employees who have been with Storvik for 25, 30, 40 and 50 years respectively. We wish – on behalf of all of Storvik – to pay tribute, recognize and thank outstanding and loyal employees.

-

New delivery with our robot welder

Company

This autumn, Storvik carried out a new delivery to a Norwegian aluminum smelter.

-

Storvik are proud of their team at Elkem

Company

Storvik has been 20 strong during the planned audit shutdown at Elkem in Thamshavn. The work has consisted of changing over 100 meters of cup work, changing the chisel machine and updating its stand, and changing the bearing in the gate wheel. The work involved 1,500 hours and 20 employees working day and night respectively. The work was carried out with the best precision and without incident.

-

Veronica Danielsen new CEO of Storvik Mosjøen AS

Veronica Danielsen has recently been employed as CEO at Storvik Mosjøen AS. Veronica comes from the position of acting department manager and order coordinator at Storvik in Mosjøen. Danielsen is from Mosjøen and is well acquainted with the local business world.

-

Storvik proud sponsor of Vinnutrappa

In January 2022, actors from local businesses, led by Storvik, collected funds for the realization of the Vinnutrappa project in Sunndal.

-

Storvik sponsors the sport

Storvik is a proud sponsor of 23-year-old super heavyweight boxer Brage Hansen Lange from Sunndalsøra. Brage recently won his first Norwegian champion title and has ambitions for a place in the national team. He spends the holidays at Sunndalsøra, and currently lives in Oslo where he works and trains for IF Ørnulf Boxing Club. Brage is very dedicated to his sport.

-

The right skills for a sustainable future

Through further education, in a collaboration with Hydro and the vocational school in Viken, Storvik aims to raise its professional resources in the company. At Storvik we are working actively towards a sustainable future. UN’s sustainability goal number 4 focuses on a good education and is the foundation for our strategic investment in further education. In addition, further education helps ensure that Storvik will be at the forefront of ever higher industry requirements regarding product quality and employee competence. By enabling each employee to achieve their professional ambitions, Storvik shall be a preferred workplace with room for development and growth. Storvik is a global and forward-looking company, which is at the top worldwide with quality as its hallmark. Our people are our most important resource and by constantly being updated professionally and offering a high level of competence to its employees, Storvik can continue to offer the best products and services of the highest class, in a rapidly changing world.

-

The Storvik guys on a historic job journey

In weeks 24-25, we carried out a successful “splitting” of the fire generator at Njord Bravo. Close cooperation between our engineering department, mechanical department and IRV-AS made this assignment possible.

-

Successful audit for Storvik

Last week we had a successful audit of quality and environmental management systems. The audit lasted four days with intense reviews of all departments. DNV is our certification body, and we were all very impressed with the expertise they bring.

-

Storvik is a proud sponsor of the Sunndal team for Vivil-Lekene 2022

Storvik is a proud sponsor of the Habilitation Service’s team from Sunndal who participated in the Vivil-Lekene 2022.

-

Strengthening the cross-border collaboration

Company

With an emphasis on strengthening the cross-border collaboration, we had a successful day with our suppliers and partners in the Czech Republic this spring in Prague. Very well facilitated and arranged by our staff in Prague.

-

Storvik Supports Local Football Team

Storvik supports the local community and is a proud sponsor of Kvass/Ulvungen. In March, Kvass/Ulvungen had a training weekend to promote girls’ football. Storvik contributed with, among other things, gym bags and water bottles. The training weekend was for J12 and J17, with several training sessions, social activities, accommodation at Grendahuset at Leikvoll, and inspiring training with Johnny Bach who is a game developer in KBK.

-

Decreasing the aluminium productions carbon footprint

Company

Storvik has through years of experience and expertise developed a proprietary iron quality structure called PjN-G. This special structure of grey cast iron ensures a quality of iron that prolongs the furnace tending tools lifetime by proven 8 to 10 times compared to our competitors, in turn making the aluminium production more sustainable. Knowing that on average, 1.9 tonnes of CO2 is emitted for every tonne of iron produced (bellona.org), the improved lifetime on the Storvik furnace tending tools vastly decreases the aluminium productions carbon footprint.

-

The Storvik Group invests in Mosjøen

Company

Storvik has so far invested about 40 million NOK in buildings and machinery in Mosjøen and plans similar investments in the years to come. We have entered into an agreement for the purchase of additional area, which is being implemented these days. In addition, we are working with Vefsn municipality to put in place an option agreement for a larger additional area on Baustein for further growth. The board and management of Storvik are very pleased with the result and development of operations in Mosjøen since we re-established Storvik in Mosjøen in 2018. We are optimistic about the future, based on the positive development we experience with our established customers, and we see interesting development opportunities with all the new establishments that are now coming around us at Baustein.

-

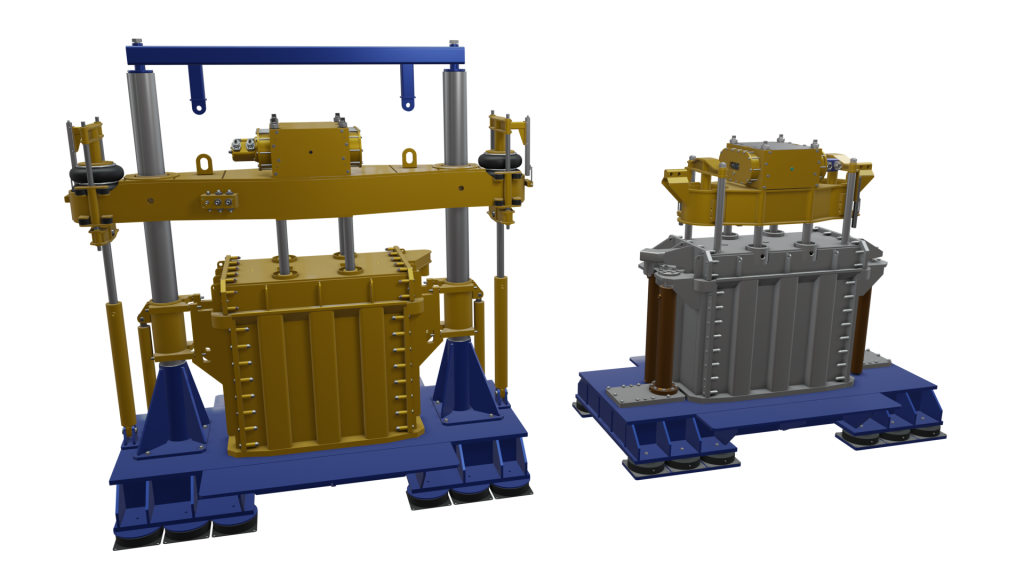

New Contract for Thimble Presses

-

The strong women behind Storvik

The story of Storvik is about entrepreneurship, creativity, and viability for over 100 years. Storvik has been a large part of the development of Sunndal as an industrial site, and it has been claimed that the development in Sunndal in many ways illustrates the modernization of Norwegian society through the 20th century. Over the years, Storvik has expanded in various areas. From local acquisitions to international sales agreements and commitments that have helped strengthen the company. What perhaps not many people know about are the crucial roles the woman behind Storvik has played in the course of company history.

-

Storvik sponsors new Vinnu Arena at Leikvin Kulturminnepark

Storvik supports the local community in Sunndal and is a proud sponsor of the new Vinnu Arena.

-

Guard Rail Cutter

In the fall of 2021 Storvik signed a contract to deliver a “Guard Rail cutter” for Arvid Gjerde. This implementation cuts old road railings with the help of a crane.

-

How we work with HSE every day at Storvik

Company

Health, safety and the environment (HSE) is one of the cornerstones of everything Storvik does. HSE is not a task that starts and ends with the individual project – it is a continuous effort. We have no one to lose, so the safety and security of our employees is our most important task.

-

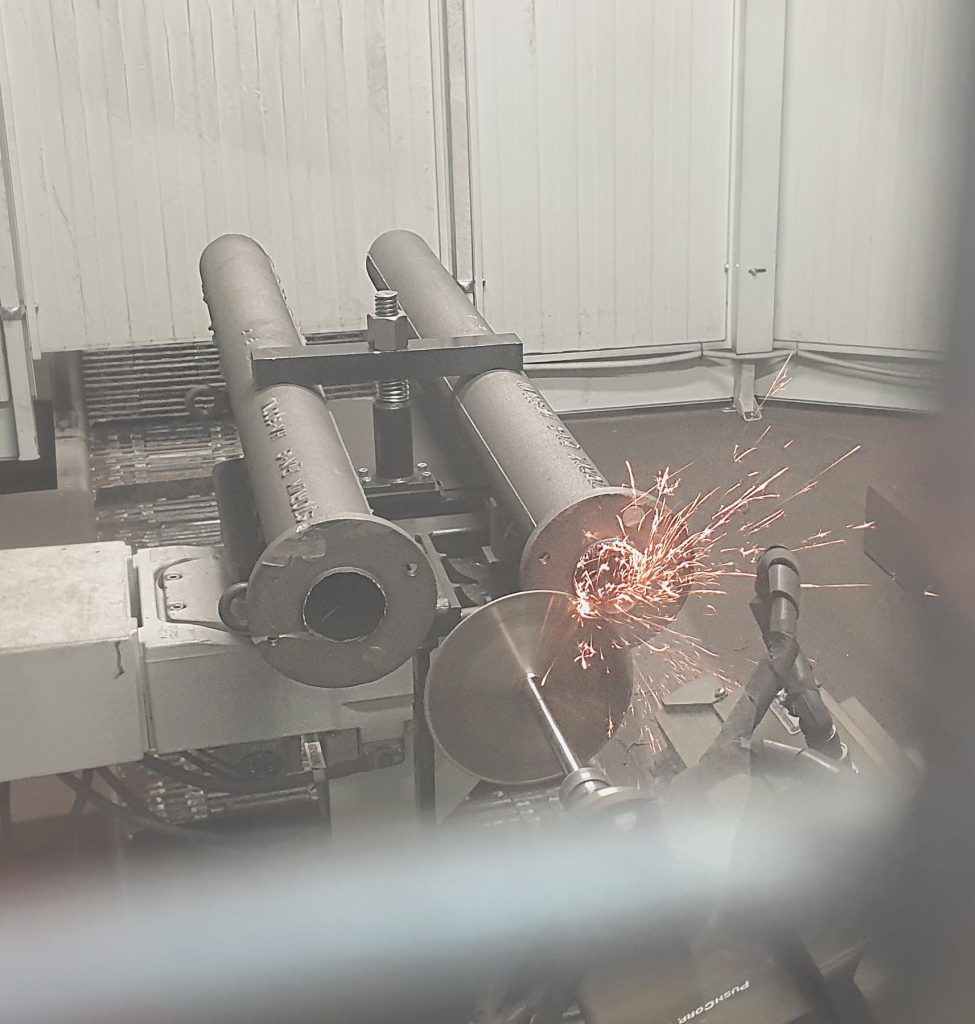

Europe’s most advanced foundry

Company

During the production of castings, grinding of the products can easily become a bottleneck as this is labor intensive and requires a large degree of manual grinding and handling. Our foundry in the Czech Republic, has been working for a long time to improve this and we can now proudly launch the solution – robotic grinding machines. Not only does this eliminate the bottleneck, but this is an extremely important measure for improved HSE. The solution means that the operator no longer has to grind manually and will then not be exposed to risk of cut injuries, dust, noise and strain on joints.

-

The world’s longest Sherpa staircase, up Europe’s highest waterfall!

In a few weeks, players from the business community in Sunndal, led by Storvik, have collected NOK 865,000 for the realization of the project Vinnutrappa. Vinnutrappa is a project were sherpas from Nepal will build a mountain hiking trail and staircase next to Vinnufallet, Europe’s highest waterfall. We experience great commitment and willingness to contribute to building the Vinnutrappa, we are many who see the importance of and the importance of realizing this project. The actors focus on attractiveness in the region and see this as part of ensuring access to local skilled workers. We want to send a clear signal that we will contribute to realizing good projects that create synergies in the region, this will increase our competitiveness in the long term.

-

Storviks project for new rail-rigs is in the works!

Last year Storvik entered a new contract with Arvid Gjerde AS for the supply of new trucks, called “Rail Rigs”. These are advanced trucks for setting up the poles for railings along the roads.

-

Steps towards greener aluminium

Storvik has entered a new contract with Hydro Aluminium Sunndalsøra (HASU) and Technology and Operational Support (TOS) for development of new technology for baked anodes.

This contract is possible by the help of Innovation Norway which funds parts of the contract. -

Merry Christmas and Happy New Year!

Greetings to all our customers, employees and business partners, we wish you a Merry Christmas, and a healthy and prosperous New Year.

-

Increased investment in conveyor belts and industrial rubber

Storvik and Lutze Conveying Norway enter into a collaboration to strengthen the position towards customers in the region, who need service and maintenance of conveyor belts and accessories. The parties have cooperated for many years, but now see more synergies by entering into closer cooperation.

-

Storvik invests in Roadtech AS

Company

Storvik (Storvik-Holding AS) has become an investor in Roadtech AS, a company that develops sustainable solutions for traffic snow poles and smart technology for safer roads.

-

Cluster collaboration for a greener future

Company

Storvik is proud to be a participant in the sustainability project “Action Now”, which is a collaboration between BDO, KBK in Kristiansund and local business. “Action Now” aims, in collaboration with local businesses, organizations and public authorities, to promote the UN’s sustainability goals.

-

New Apprentices

Company

We are focusing on apprentices and this year we have welcomed four new apprentices at Sunndalsøra and one new apprentice in Mosjøen. Our apprentices help to strengthen our professional environment. At Sunndalsøra we have Malin Øyen and Martin Haugen as apprentices in the sheet metal work profession, Daniel Hoås Wennevold and Paul Magne Leangen as apprentices in the industrial mechanics profession, and in Mosjøen we have Marius Aune who is an apprentice in the welding profession.

-

Have a wonderful summer

On behalf of Storvik we wish our customers, employees, partners and suppliers a wonderful summer!

-

Storvik has entered a multimillion-dollar contract with Elkem

Company

Storvik has signed a contract for delivery of cast iron products to Elkem’s seven locations in Norway and in Iceland. The multimillion contract is valid for a period of 3 years. Storvik has worked closely with Elkem, and the collaboration has been fruitful for several years. The previous framework agreement was signed in 2018 and was replaced by the new contract signed May 1st 2021.

-

Global Growth for Storvik Cast Iron and Steel Products

Storvik is a global supplier of cast iron and steel products for the process metal industry, with main focus on the aluminium industry. Our proprietary alloys developed jointly between the foundries, our customers and Storvik is the main key to success and good lifetime and overall performance of our products. Ronny Reitan, Manager Cast Products is showing us the warehouse in Sunndal, Norway with products for the aluminium and ferro-alloys industry in Norway and Sweden. The warehouse ensures smooth deliveries and short response time for the industrial users. Storvik supply cast iron and steel products for the process industry from Tasmania, South of Australia to North America and has grown to be a major business area in Storvik.

-

New Contract with Arvid Gjerde AS

Storvik has entered into a new contract with Arvid Gjerde AS for supply of two new trucks, so called “Rail Rigs”.

-

Storvik wins Innovation award from Novelis

Novelis is the world’s largest producer of rolled aluminum sheet, with operations spanning 11 countries and 11,000 employees. In March 2021 Storvik ranks number 3 for the Innovation award. Our colleague Helgi Magnusson, Managing Director of Storvik Iceland, has developed and delivered multiple systems within metal treatment (tapping and furnace tending), which lead to the award. Helgi Magnusson says;

-

New technology at Storviks daughter company Protech

Storviks daughter company Protech in Sunndalsøra has installed a new automatic process line for robotic welding and handling of anode yokes. The line installed by Protech is based on the same principles as the line installed by Storvik at Alcoa Mosjøen, however the line installed in Alcoa Mosjøen is fully integrated into the rodding plant. The robotic line improves our employees HSE and the quality of repairs, compared with traditional manual repair. Storvik are continuously in dialogue with our costomers for implementation of new technology, to make more effective processes and to increase the value for our customers.

-

New Lathe installed at Storvik in Mosjøen

Willas Trettbakk shows the new Lathe machine installed at our location in Mosjøen, we now have the possibility to make bearings, axels, bolts and other machined steel parts which is critical parts for our local customers.

We continue to expand and develop our capacity and machinery in Mosjøen says foreman Tommy Sunde.

-

New CNC gas/plasma table for Storvik in Mosjøen

Storvik has invested in a new CNC plasma table at our location in Mosjøen. The table can handle plates with dimensions 6×2 meters. This gives us better flexibility and we can react quick on urgent matters for our customers in the region says Department Manager Bjarte Valåmo. The MAXPRO200 plasma cutting system is designed for powerful, high-capacity automated cutting. The user-friendly system works with either air, oxygen or nitrogen as plasma gas, and combines fast cutting speeds and fast process changes to maximize productivity. Advanced Hypertherm technology – including LongLife® technology – improves cutting quality and significantly increases service life to reduce cost per part.

-

Storvik is hiring apprentices

Storvik is hiring apprentices at both Sunndalsøra and Mosjøen

-

Merry Christmas and a Happy New Year!

Greetings to all our customers, employees and business partners, we wish you a Merry Christmas, a healthy and prosperous New Year.

-

Welding Certificates

Thomas Egan, Andreas Resell Røv og Mathis Sjursen have just finished certification test for welders – Well done! The test was performed on two stainless steel pipes and one standard steel pipe. We now hold 20 welding certificates, most of those certificates are done in fixed pipe position of 45 degrees. This allows us to perform many various jobs and our certified welders are attractive in the market.

-

Storvik with virtual stand during Future Aluminium Forum Digital

Future Aluminium Forum Digital is a conference focusing on the digitalization of the aluminium industry. In the future these digital events will be a valuable meeting place for our clients and partners. Storvik will exhibit with a virtual stand during Future Aluminium Forum Digital on December 2nd and December 3rd. Our team of skilled professionals is ready to answer your questions and discuss solutions for the future. We have a selection of animations showing our machinery, equipment and solutions for the aluminium industry.

-

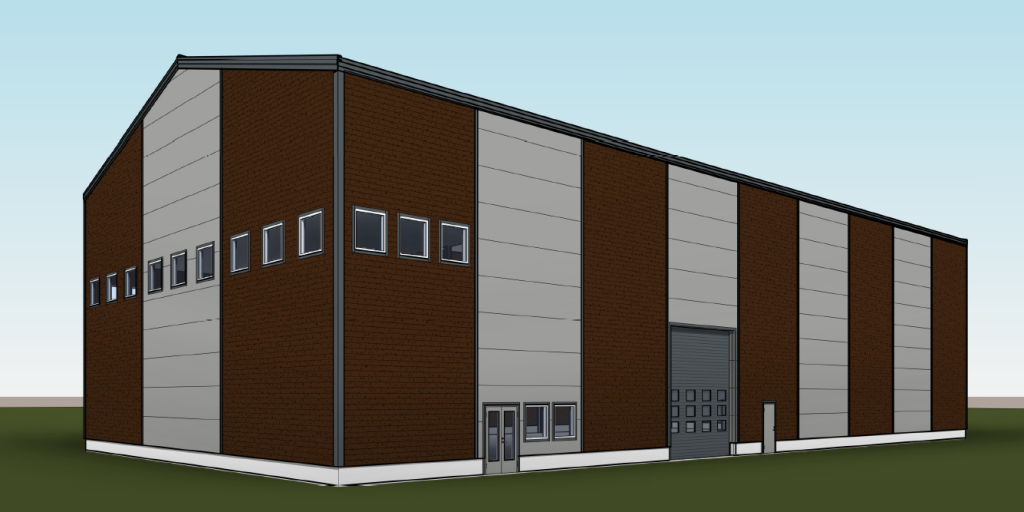

Storvik opens new mechanical workshop in Mosjøen

Storvik recently opened a new industrial building in Mosjøen. With a location close to Alcoa Mosjøen primary aluminium smelter, our focus is serving the aluminium industry. In addition, there are several other interesting market possibilities within hydro power, construction and other process industry. In general, the region has a great potential and this was also important for us when the decision for expansion was approved by the Board of Directors. This is one of the largest investments for Storvik for last few years. Our ambition is a twin of Sunndalsøra, serving the industry with mechanical services, production, engineering, projects and consumables. The building consists of modern workshop for mechanical activities in addition we have offices and storage area. We are now focused on installing new machinery and equipment and employing more personel. Storvik has an option with the local government for expansion within the next few years.

-

Webinar Furnace Tending Tools

Storvik are looking forward to invite the audience to a live Webinar of Furnace Tending Tools for Casthouses on the 26.11.2020 at 12.00 CET.

-

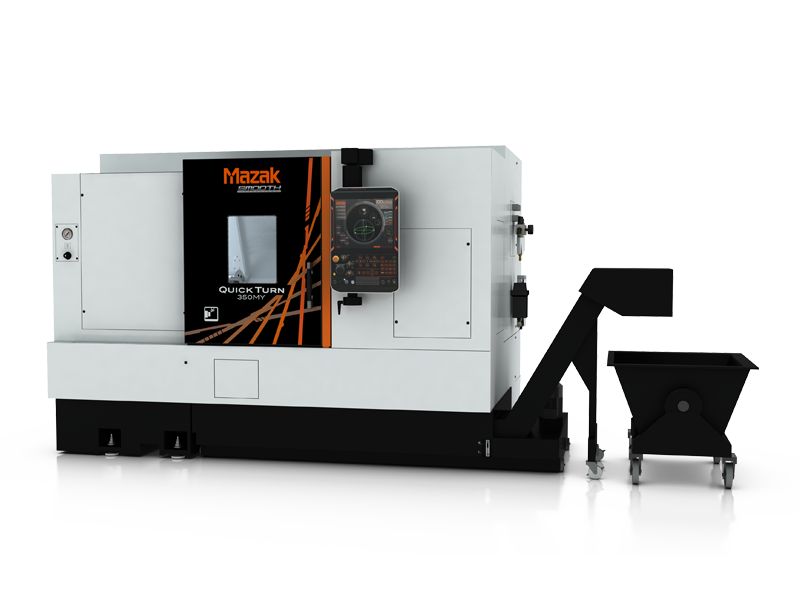

New CNC Lathe Mazak 350MY Machine

Storvik has invested in a new CNC Lathe at Sunndalsøra. The new machine is placed in the machining workshop named “Smia”.

-

Pangstart 2020

Storvik and Vindel continues the “Ideaprize” by Heggset Engineering and launches “Pangstart 2020”

-

Storvik delivers product with new innovative design

Company

Storvik is delighted to announce that Cast products has received an order from Kubikenborg Aluminium for 30 pieces of new type of Sow Moulds, the value of the order is over a million NOK.

-

New contract for Storvik in Tasmania, Australia

Company

Storvik is very happy to announce a new contract to deliver a 6-month supply of tapping pipes to The Bell Bay smelter of Rio Tinto in Tasmania, Australia

-

Storvik Kristiansund moved to new offices!

Company

Storvik Kristiansund has been moved to new offices in Technoport since 1st of May this year.

-

Approved innovation (FoU) projects awarded by Innovation Norway

Company

Both Storvik in Mosjøen and Sunndalsøra / Kristiansund has been awarded with two feasibility studies, for very promising and exiting Storvik products, by Innovation Norway.

-

Storvik has entered a multimillion-dollar contract with Hydro

Company

Storvik in Sunndalsøra has signed a contract for the supply of cast iron and cast steel products to the five Norwegian Hydro plants, which has a multimillion-dollar value, for a period of seven years. Storvik has worked closely and well with Hydro since the 1990s and the previous framework agreement was signed in 2013 and was valid until the new contract came into force on 1 July 2020.

-

The Cost Improvement Award

Company

In Q1 2020, Storvik had the honour of receiving the cost improvement award from Hydro. Behind this lies solid experience within the process industry and many years of optimization and development. We are very proud of the collaboration we have with Hydro and the results we have achieved.

-

Approved apprenticeship provider in automation

Company

In May 2020, Storvik was approved as an apprenticeship provider in the automation field. This is a developing trend in our industry, with automation of processes and Storvik wants to invest more in this field. We believe that through automation of processes we will increase our share of Norwegian production and at the same time strengthen our own competitiveness. We hope to get an apprenticeship in the automation profession this year.

-

Bjarte Valåmo – new Manager for Storvik in Mosjøen

Company

Storvik has established itself in Mosjøen and a new industrial building is under construction on the Baustein Industrial Area. It has been important for former Manager Jan Sandbukt that the new building should be in place before he now passes the baton to Bjarte.

-

Storvik’s Response to Covid-19

Company

We have summarized information about our operations and what we are doing to secure the safety of our employees, customers, suppliers and communities.

-

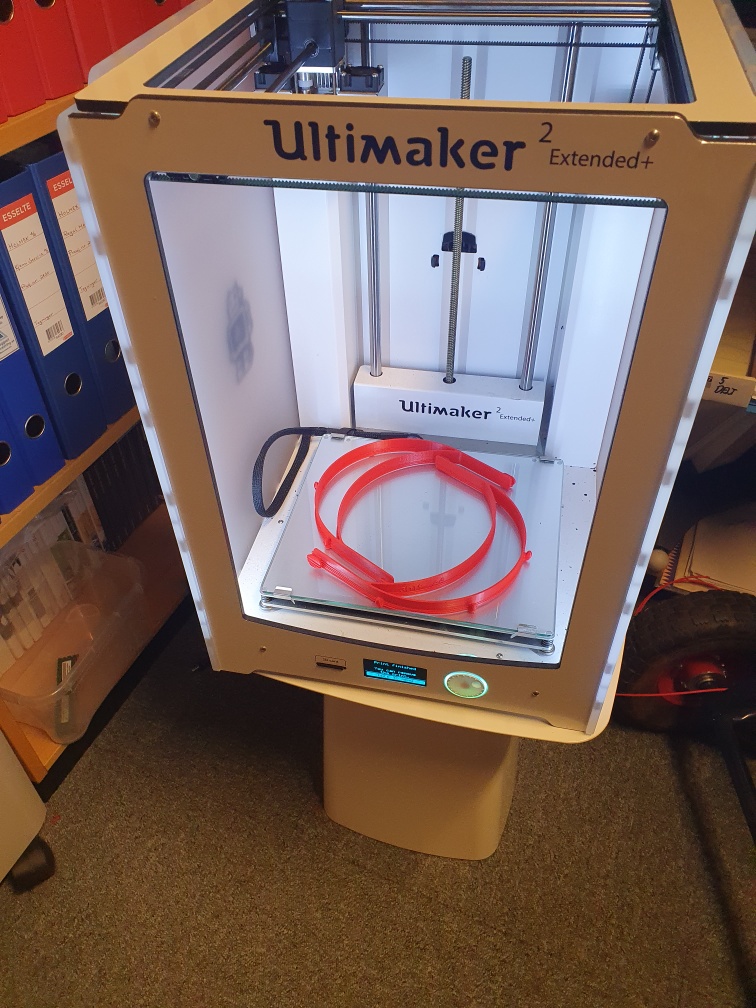

3D printed protection equipment

Company

On Tuesday evening, March 31, the municipality of Kristiansund went out with a prayer addressed to everyone who has a 3D printer. They have an urgent need for protection equipment, more specifically a so-called “visor” that protects the face. Very simple fasteners can be printed on 3D printers and Storvik will contribute to this. Wednesday morning, the first batch of fasteners went to print at Storvik, and we are very happy to make a small contribution to the health care system in this way.

-

Jubilants 2019

Company

At Storvik we have many good and loyal employees, the four gentlemen in the picture have been part of our team for 25 and 40 years respectively. The picture is taken in connection with the awarding of appreciation from the company for long and faithful service

-

Apprenticeship 2020

Company

This year we are looking for apprentices in the following subjects:

- 2 industrial mechanics

- 1 CNC

- 1 welder

Applications can be sent to Operations Manager at the Mechanical Department, Ole Ivar Kvande, phone: 99 25 75 39 or email: oik@storvik.no

-

Groundwork in Mosjøen has started

Company

Groundwork for our new industrial building in Mosjøen has now started. The building is scheduled to be completed by the end of June 2020. The new industrial building is an important part of Storvik’s future business strategy, and we are very excited to see the development of this project. The new industrial building will have a base area of 45 x 18 meters, which will provide Storvik with the necessary facilities to handle today’s contracts, while also having plenty of room for several new assignments.

-

SuSu Arena 2020

Company

Storvik participated in SuSu Arena 2020 on 23 January and had a quiz competition.

Many had answered our quiz and of those who had everything right we have drawn Simen Svanberg Larsen as winner of Air Pods Pro.

Congratulations!

-

Storvik invests in new milling machine

Storvik has recently invested in a new milling machine, the Mazak 530C SMOOTH. This is a 3 axis machine with X, Y and Z axis. Where the axes have a travel of X 1050mm, Y 530 mm and Z 510 mm. Spindle speed 12000 rpm. This gives Storvik the opportunity to produce highly customized series of machined part for various applications.

-

Storvik aquires parts of the Czech foundry RKL Slevarna s.r.o.

Company

After several years of negotiations, Storvik succeeded in becoming a co-owner of the iron foundry RKL.

-

New contract in Iceland

Company

Rio Tinto Alcan (ISAL) enters into agreement with Storvik for supply of cast iron parts. Storvik will hold the parts close to the smelter and supply according to their need. We have similar set-up with other locations in Iceland says Director of Storvik Iceland, Helgi Magnusson. The contract is important for Storvik and herby confirms the quality of our products and that our local presences in Iceland is valuable for our end customers. The products we will supply under this contract is tapping pipes, furnace tending tools, bath tapping lids and cast iron lining.

-

New industrial building in Mosjøen

Company

Storvik has signed a contract for the construction of a new industrial building on the Baustein industrial area in Mosjøen. It will be delivered by the end of June 2020. It will have a base area of 45 x 18 meters, which will provide Storvik with the necessary facilities to handle today’s contracts, while also having plenty of room for several new assignments. Storvik wishes to thank both its own employees and Alcoa for their patience and benevolence in a demanding start-up phase for Storvik in Mosjøen.

-

The Arab International Aluminium Conference (ARABAL)

Company

The Arab International Aluminium Conference (ARABAL) is the premium platform for the aluminium industry in the Arab world. ARABAL has become an event of international repute, bringing together industry leaders from around the world to discuss current issues in the aluminium sector whilst also exploring investment opportunities. Storvik is this year attending the ARABAL for the fifth time, which is held on 19th – 21st November 2019 at the Gulf Hotel & Convention Centre in the Kingdom of Bahrain. Storvik has it the past few years experienced growth in this region and are looking forward to continue exploring opportunities here.

-

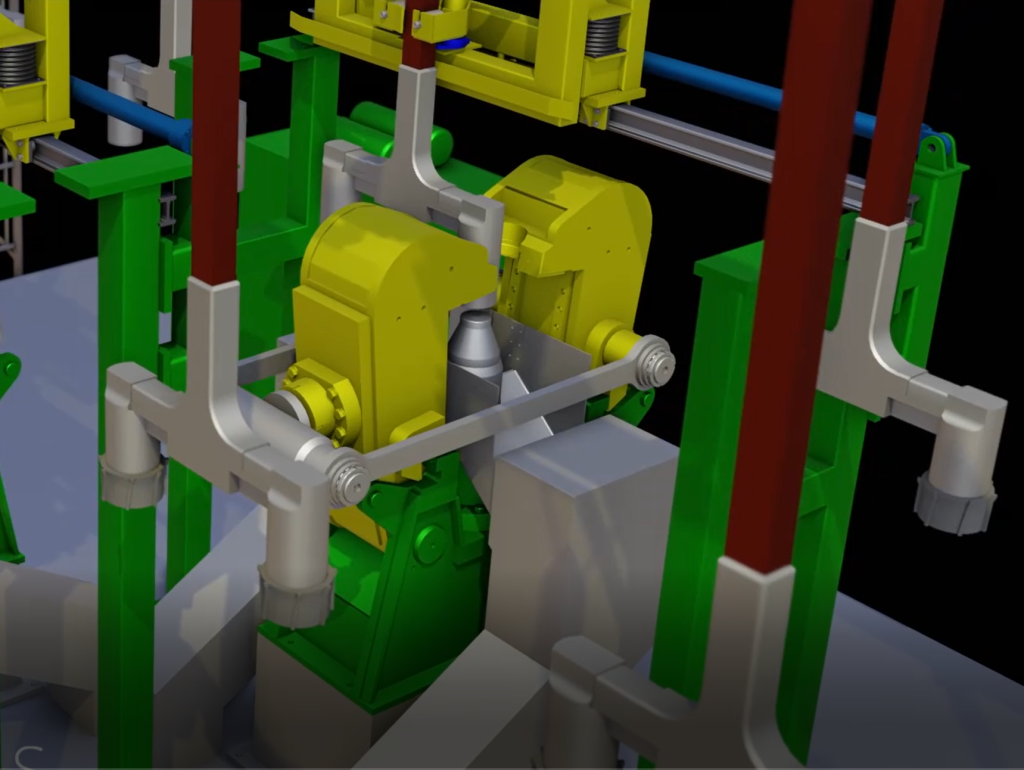

Storvik awarded million dollar contract

Company

Hydro Sunndal is modernizing the anode paste plant at the aluminium plant at Sunndalsøra. Storvik has been awarded a contract for the demolition and installation work and includes the installation of a new mixing line for carbon mass, a new ball mill, as well as the dismantling of the existing production line in the anode paste plant. The work will start in the summer of 2018 with the goal of starting a complete plant in the fall of 2019. The contract includes activities and the supply of necessary resources for design, procurement, fabrication, dismantling and installation, as well as assistance with testing and commissioning.

-

Stein Kjartan Vik – New CEO of The Storvik Group

Company

The Storvik Group (Storvik-Holding AS) has appointed Stein Kjartan Vik (43) as new CEO with effect from 1 July 2017. Former CEO and co-owner, Nils L. Sande, continues as Chairman of the Board.

-

New CEO of Storvik AS

Company

Press release: Dag Sverre Sæsbøe new CEO of Storvik AS

-

Storvik acquires Heggset Engineering AS

Company

Storvik – Holding AS (Storvik) in Sunndalsøra has entered into an agreement to acquire Heggset Engineering AS in Kristiansund. The transaction will take place with accounting effect from 1 January 2017.

-

THE HISTORY OF STORVIK

Company

From a small smithy to international big business. The story of Storvik is about entrepreneurship, creativity and viability for over 100 years.

-

New Framework Agreement with Elkem – A Long-standing Partnership Continues

Company

Storvik and Elkem are continuing their strong collaboration. The new framework agreement, signed on April 30th, 2025, runs for three years with an option to extend for an additional two years.

-

Storvik and Hycast Enter Framework Agreement

Company

Storvik and Hycast have entered into a new framework agreement that formalizes and further develops the strong collaboration the companies have enjoyed over time.

-

New colleague at Cast Products

Company

We are pleased to welcome Lars Erik Valsø to Storvik! He joined us on February 3rd as Order Coordinator and Logistics at our Cast Products department.