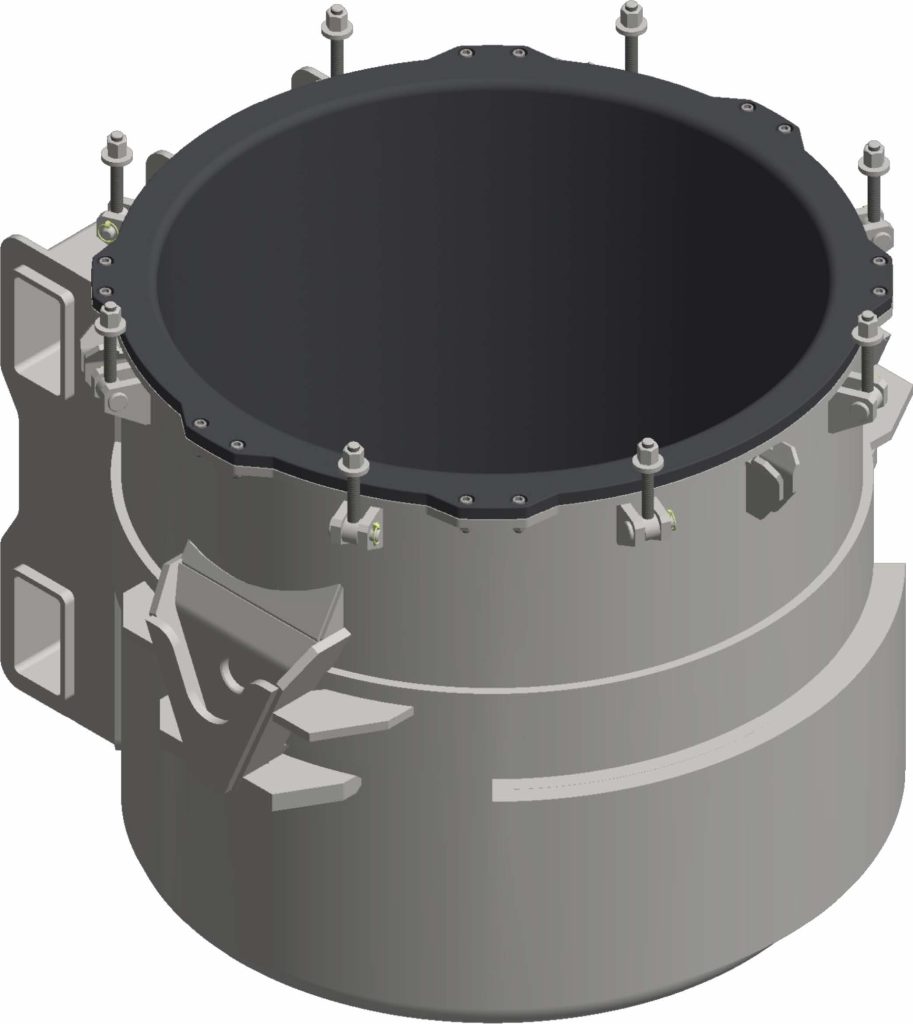

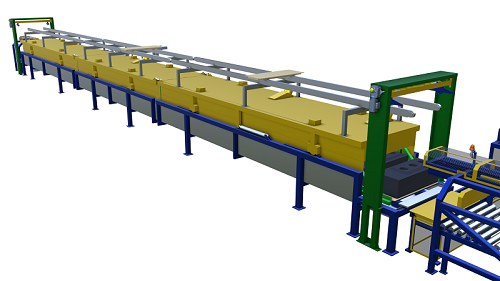

COOLING CONVEYOR

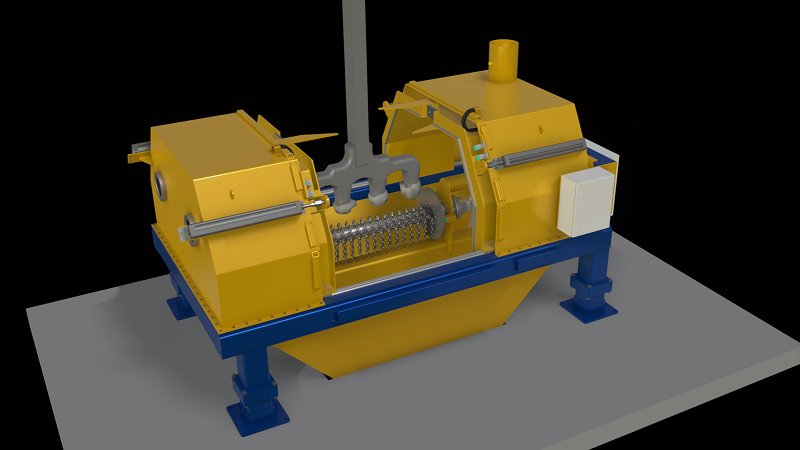

After shaping and compression of the carbon paste, the anode is still warm and soft, and need to be cooled for achieving hardness for handling.

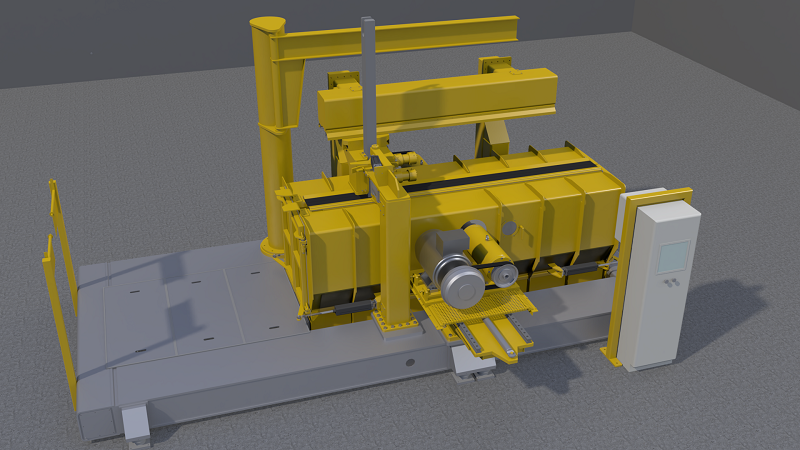

The cooling conveyor is placed inside a chassis with trough shaped bottom for collecting the used water, the chassis is formed like a tunnel. The conveyor is operating according the walking beam principle. After forming the anode, they are pushed onto a pallet. The pallet with anode enters the colling tunnel and are step by step brought through the tunnel while water is sprayed continuously for cooling the anode.

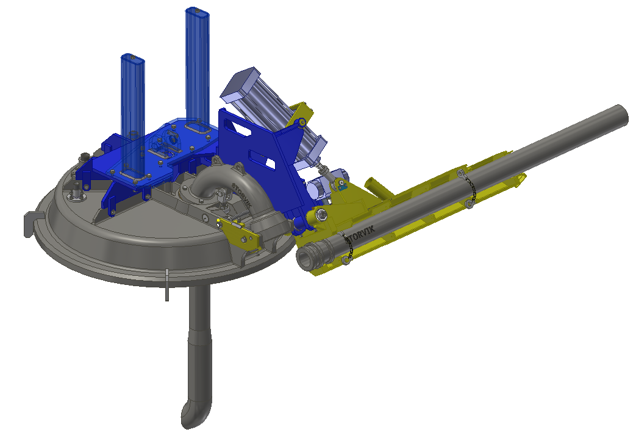

At the end of tunnel, the temperature of anode has dropped and necessary hardness for handling the anode is obtained. At the exit, the anode is rotated and pushed off the pallet for longitudinally relocation and transport on a roller conveyor.

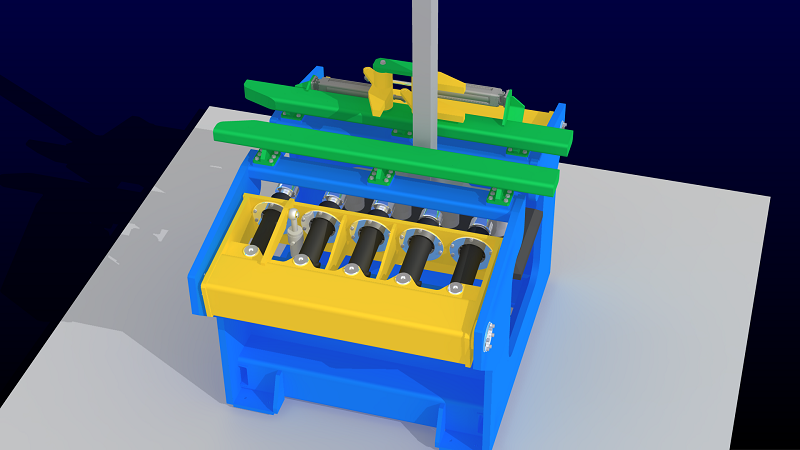

The empty pallets are simultaneously lifted and returned to initial position by a conveyor and are prepared for loaded up for a new cycle. The cooling tunnel is hydraulic operated, and the process is continuous and fully automated.

The Storvik cooling conveyors is robust and designed for easy access to all components and maintenance