Process Improvement and product development

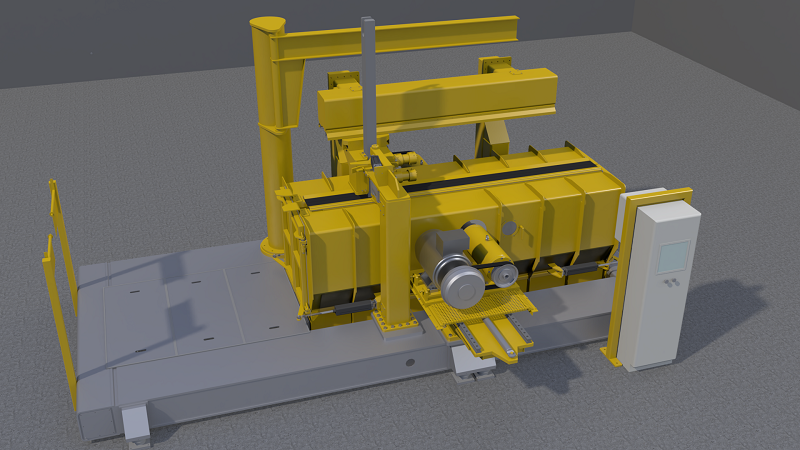

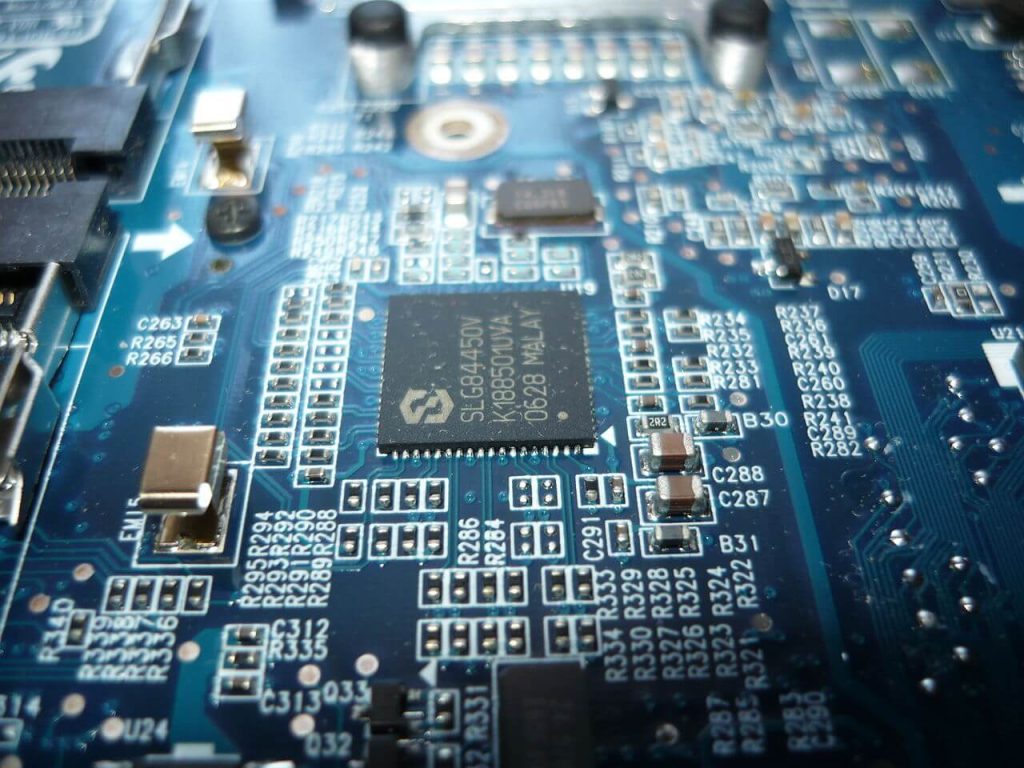

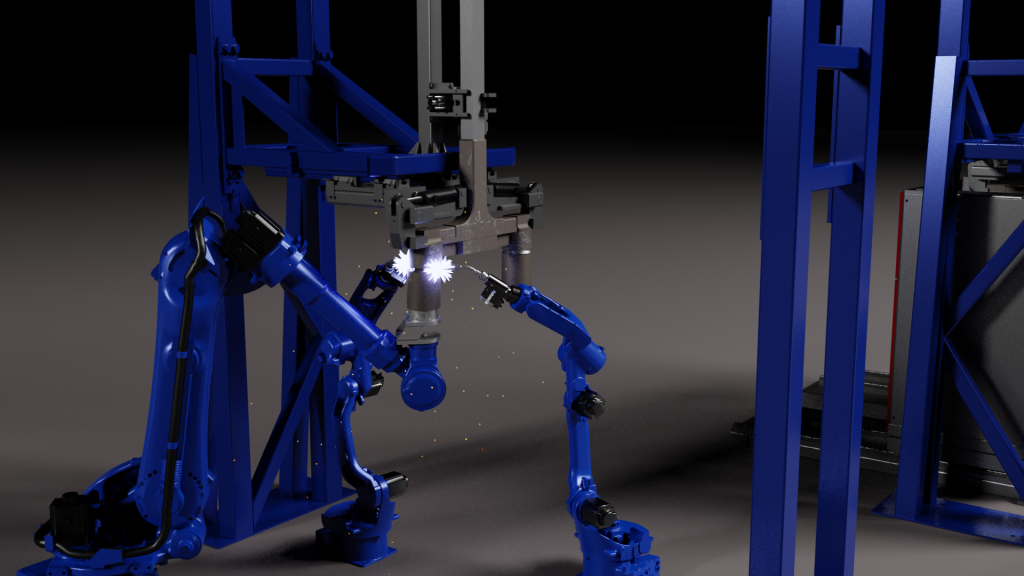

Storvik has great knowledge into the processes and machinery used in the aluminium industry through our team of experienced engineers and a large day-to-day workforce doing maintenance and modifications at Europe’s largest primary aluminium plant.

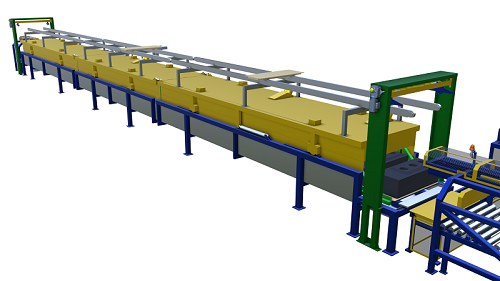

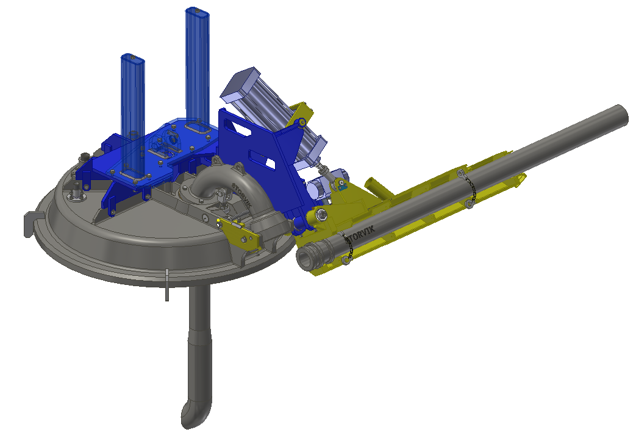

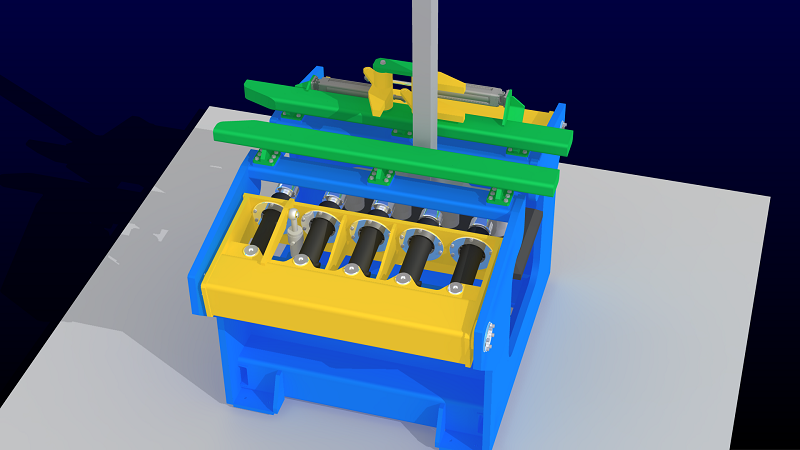

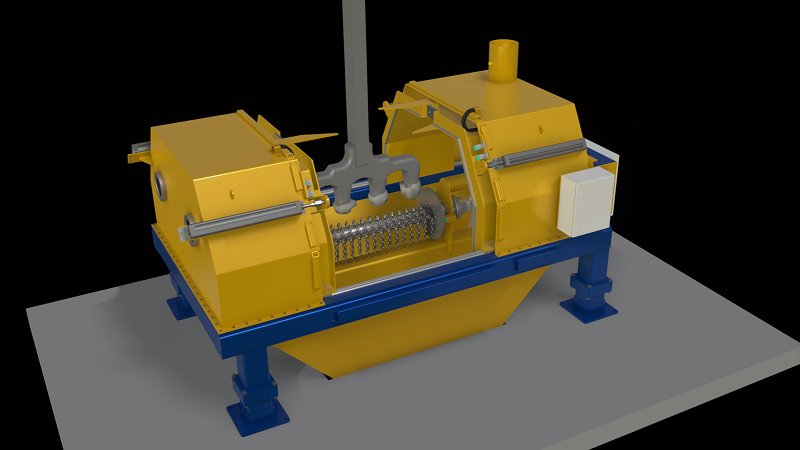

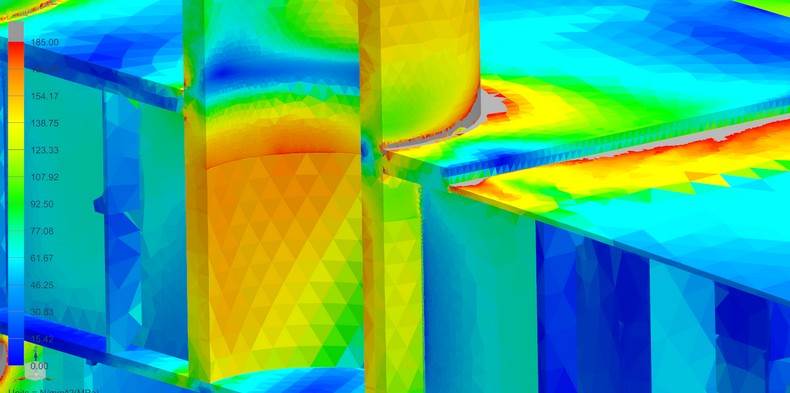

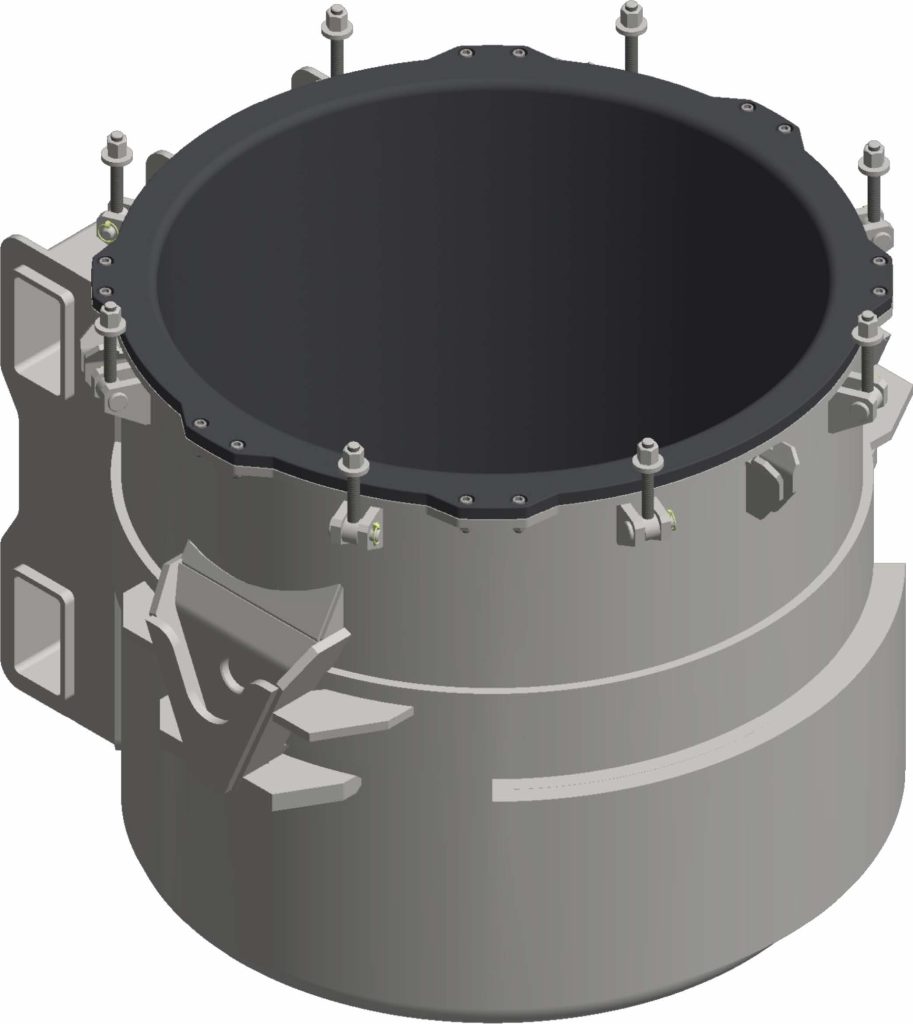

A deep understanding of the mechanisms at work in any given industry process is necessary to improve upon it. We can either design completely new products from the ground up, or adapt machinery from our existing product line to fit into our customer production line.

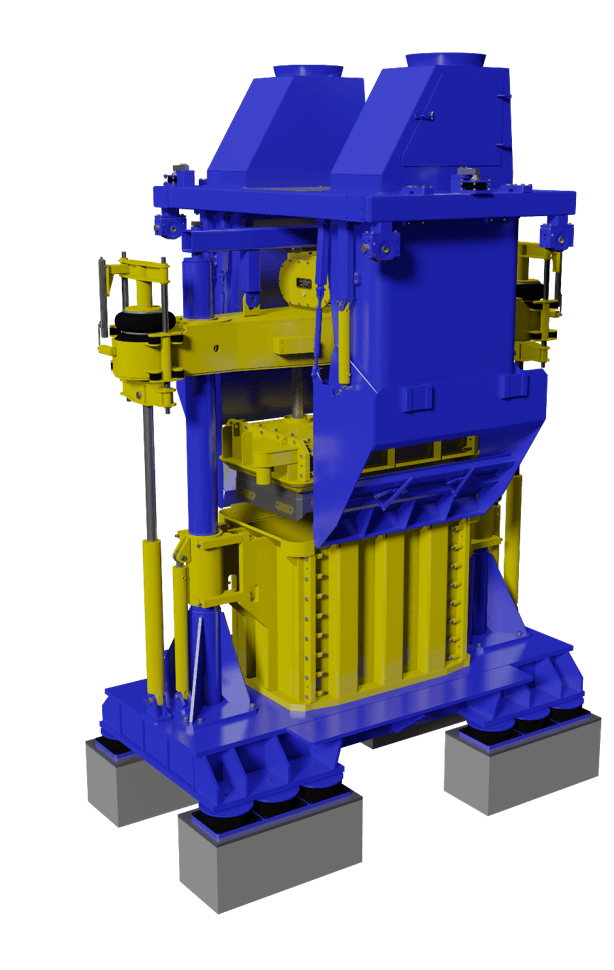

Storvik has accumulated a comprehensive knowledge base by delivering novel and improved machines and process solutions to existing workloads through decades. Several of our products on offer has evolved through numerous generations of improvements.

Effciency and cost are important factors to developing new products and processes. Abiding to international standards and regulations is a given. A strong focus on HSE in the design process is also important.