Oil & Gas Industry

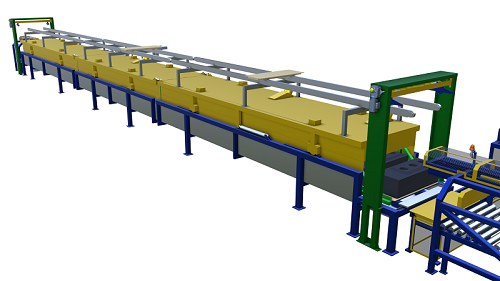

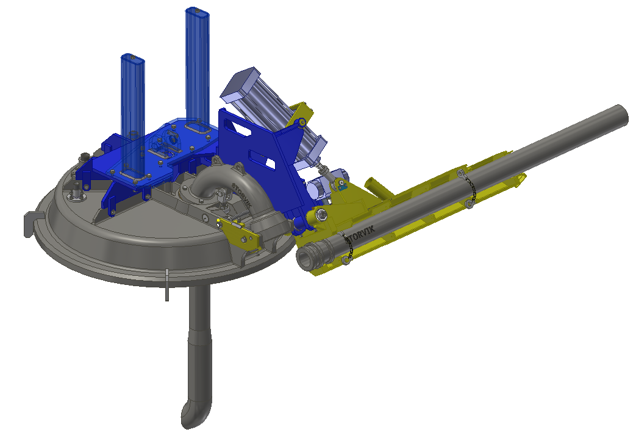

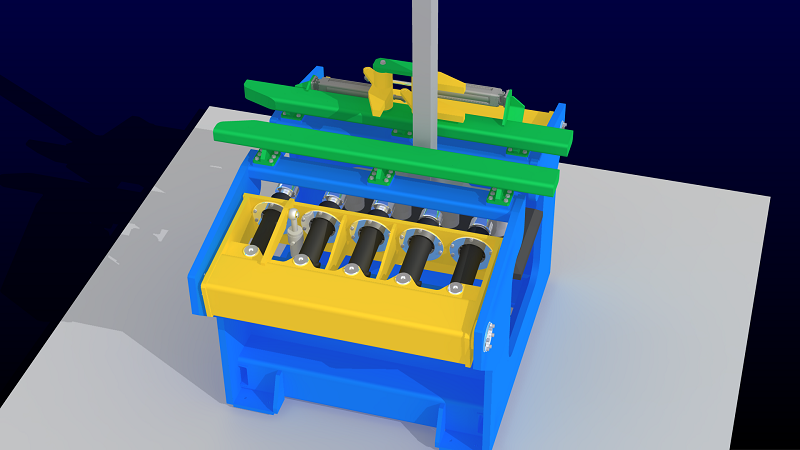

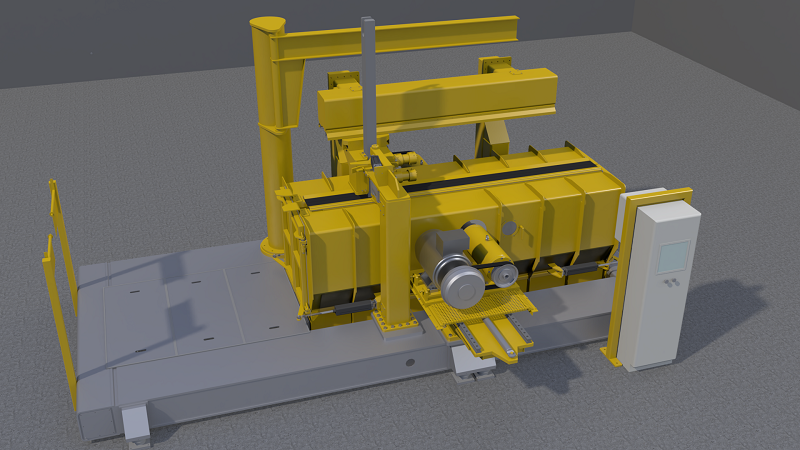

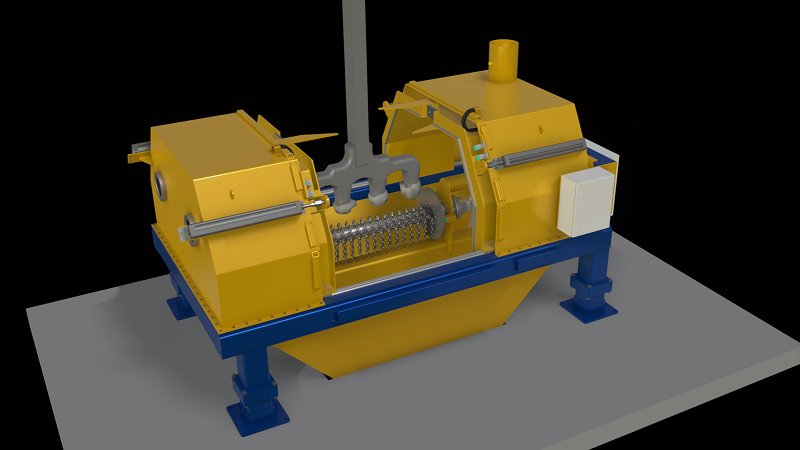

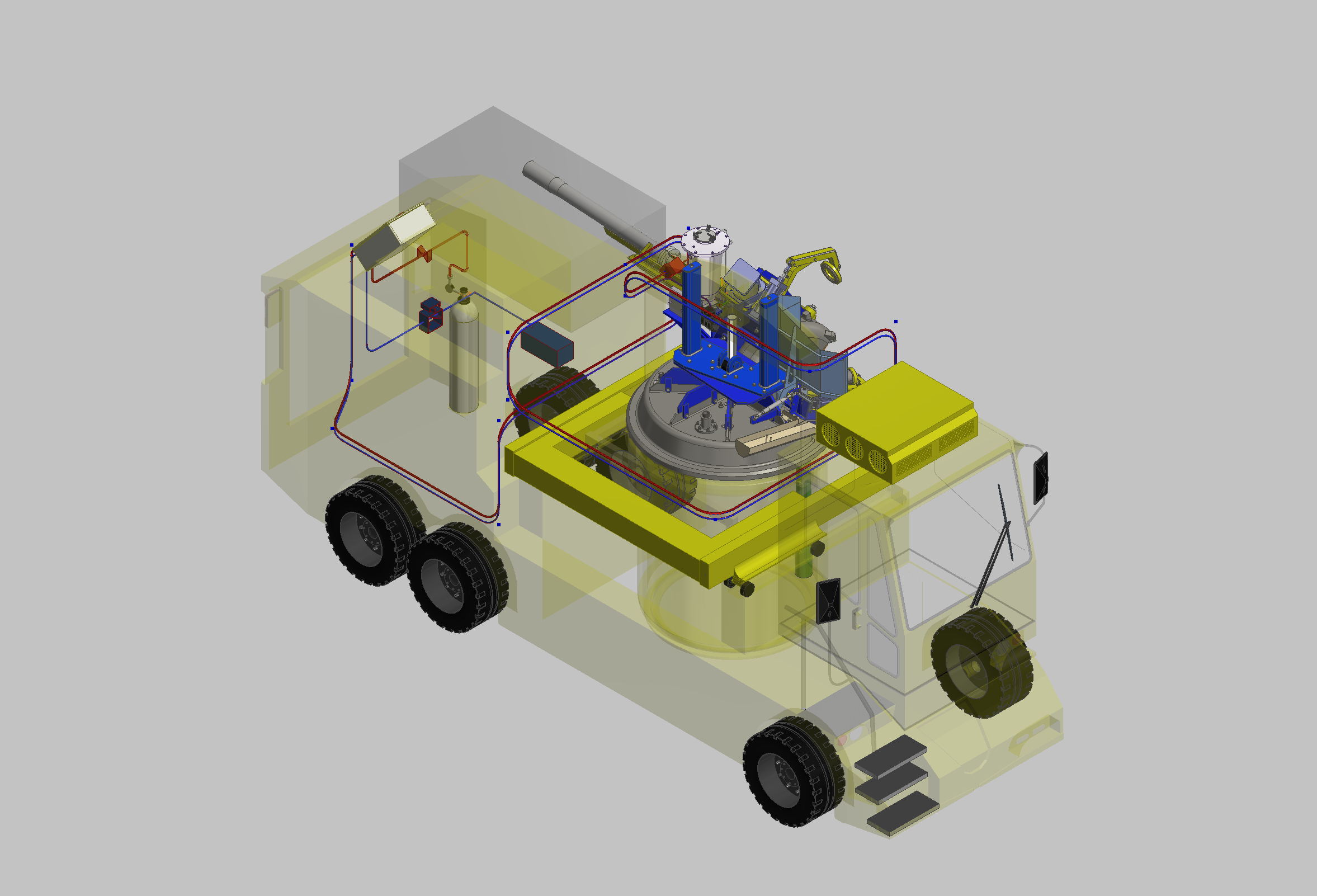

Storvik has in the recent years expanded to the oil and gas industry and provide EPC (Engineering Procurement Construction) services to the international oil and gas market. In addition to the offices in Sunndalsøra and Iceland, Storvik has an office in Vestbase in Kristiansund, where the focus is to collaborate closely with the customers to develop the best solutions for their operations. Storvik is certified according to international standards, and the company is the preferred supplier to major international companies such as Aker Solutions and Saipem.

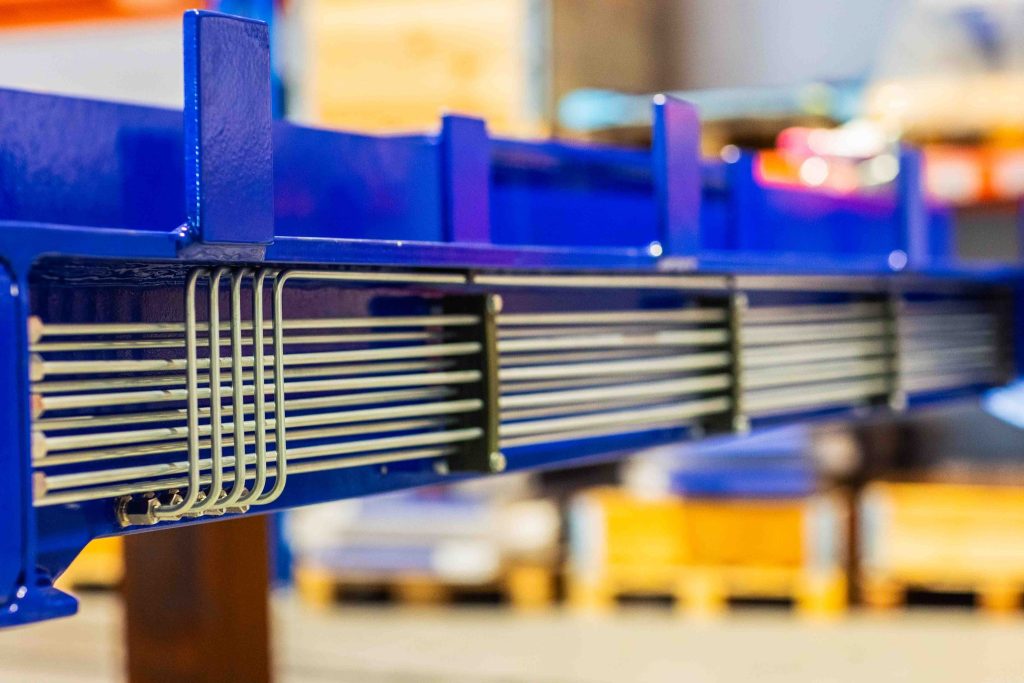

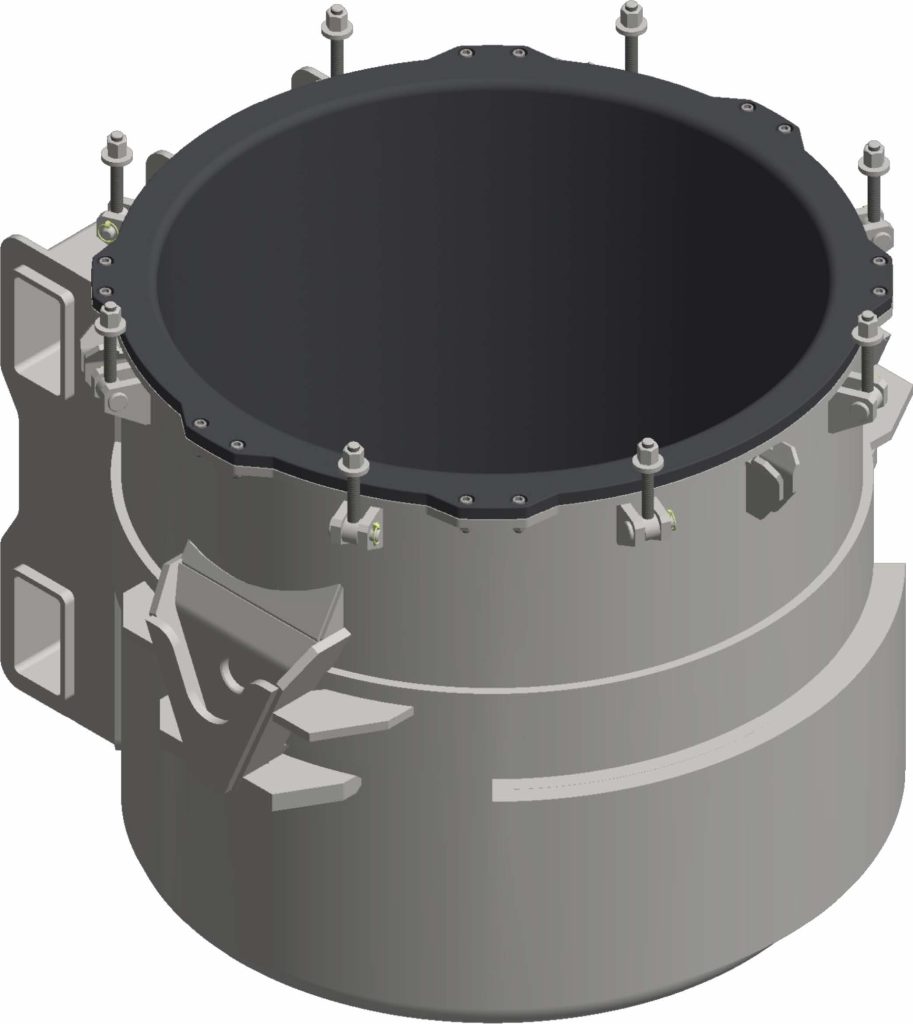

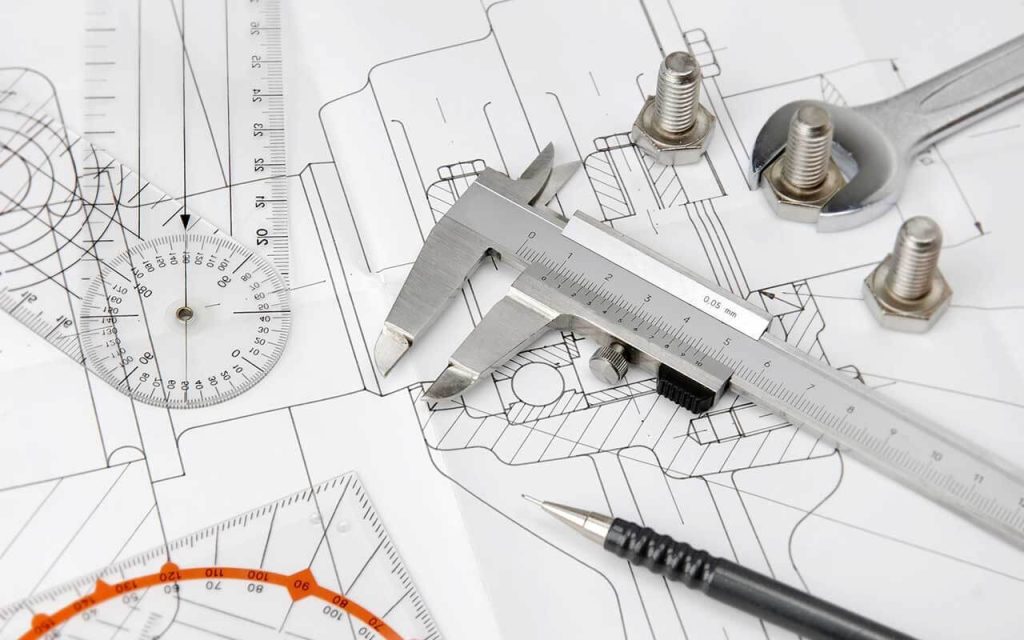

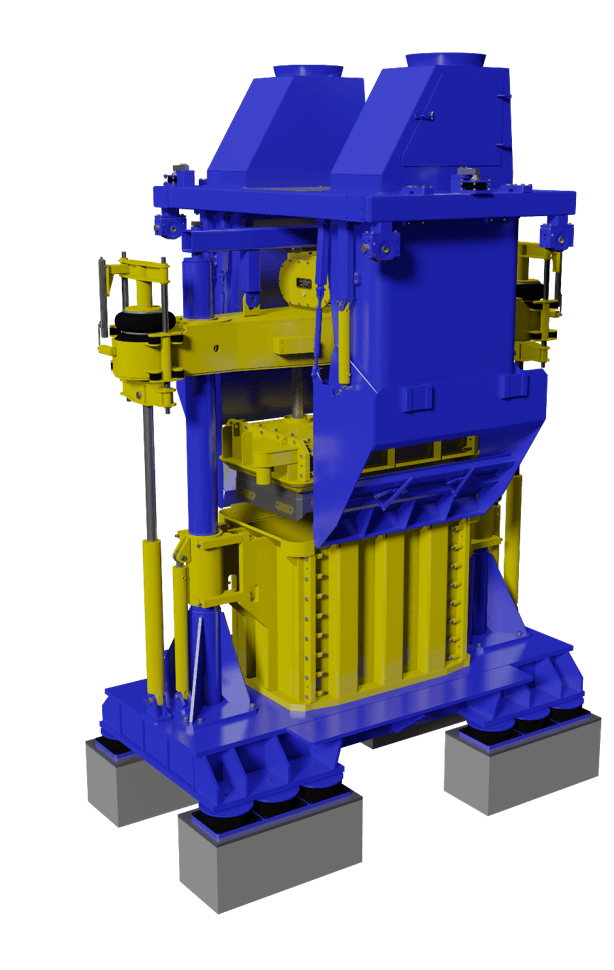

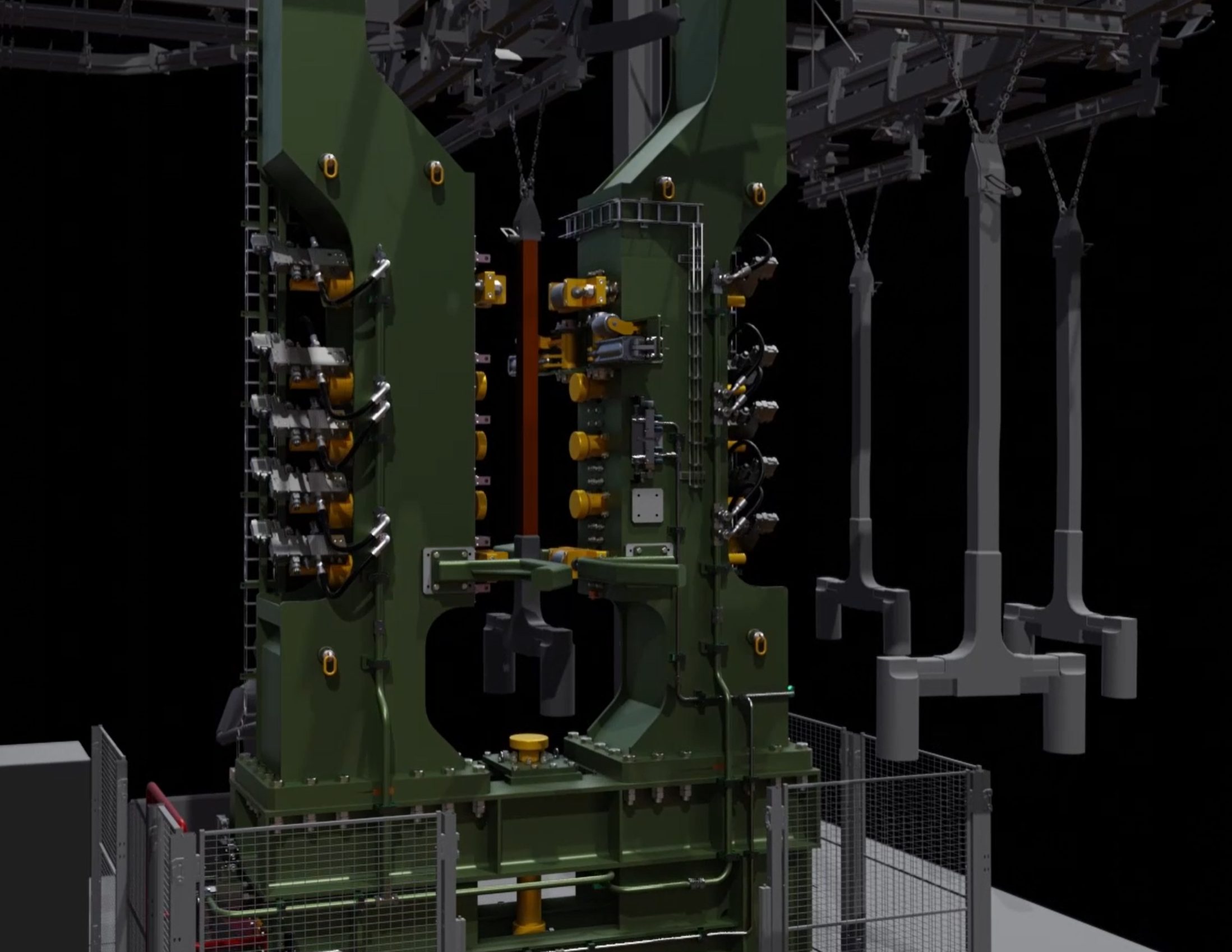

Storvik delivers steel structures and machines derived from their own design and engineering, in all dimensions and materials- from small 5 kilo components up to large 50-ton systems.

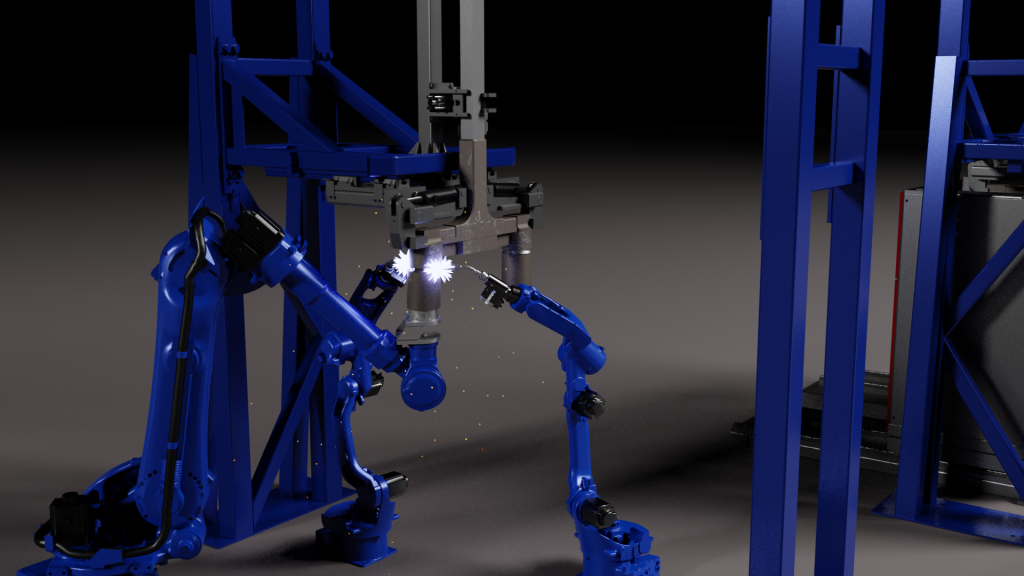

Storvik’s goods are predominantly developed through local engineering skills from the offices in Kristiansund and Sunndalsøra, combined with cost-effective fabrication from Norwegian and international partners.